Categorization:Product Information

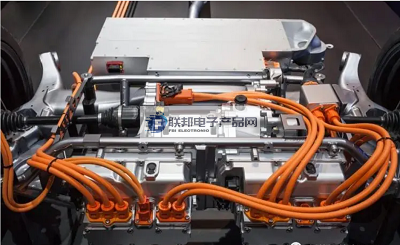

High-voltage cable is composed of conductor, insulation, sheath, shielding, aluminum foil, wrapping tape, filler, etc. 1.Conductor Currently, the conductor of the new energy automobile industry is mainly composed of annealed soft copper wires or tinned copper wires, i.e., copper wires with oxygen content less than 0.001%, and copper wires with exceptionally high purity, which have an oxygen content of more than 99.99% and will not be oxidized and embrittled. The conductor specifications of high-voltage cables are divided according to the cross-sectional area, and the current specifications commonly used in the new energy industry are 1.5~120 square millimeters. (Note: high-voltage cable conductor cross-sectional area = monofilament cross-section section × number of wires) 2, insulation and sheath current industry is more commonly used insulation materials are cross-linked polyolefin (XLPO), thermoplastic rubber (TPE), silicone rubber and so on. Orange-colored bellows is usually chosen for the shell, which plays the role of anti-wear, noise reduction, heat preservation and aesthetics. Shell and the corresponding parts of the body with, play a role in sealing, waterproof, etc., according to its heat resistance generally choose 125 ℃ materials, drive motor high-voltage cable using 150 ℃ materials.

3.Safety designThe high voltage wiring harness inside the battery pack adopts a dual-rail design, and the modules at the front and rear ends of the battery pack are connected in series, and the PTC, air-cooling fan, strong power maintenance switch, and charging pre-charging circuit inside the battery pack are all connected to the principle circuit. And the strong power of the whole vehicle is realized through the high voltage socket at the front end of the battery pack. The high-voltage socket is shielded by the plug body, which increases the high-voltage interlock function and effectively prevents the EMC interference caused by high-voltage current. The high-voltage wiring harness and the housing of high-voltage components need to be lapped. High-voltage wire harness connectors are high-voltage resistant, waterproof, ring interlock and shield connection. Harness manufacturers use plastic wire channel or metal bends to protect the high-voltage wiring harness in special locations from damage.4. Layout form In order to avoid electromagnetic interference when the high-voltage harness is transmitting strong electric current, and to make the low-voltage wiring harness interfere with the power supply of the control unit and the signal transmission, the general use of high-voltage wiring harnesses and low-voltage harnesses between the spacing between the layered design within the range of 200-300mm. For wiring harnesses that travel in the same direction and are connected to the vehicle body, a parallel arrangement is used. Ensure that the high-voltage and low-voltage wiring harnesses are side-by-side and do not cross each other, effectively avoiding electromagnetic interference generated by the transmission of power supply from the high-voltage wiring harnesses, which is mostly used in hybrid models.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!