Categorization:Product Information

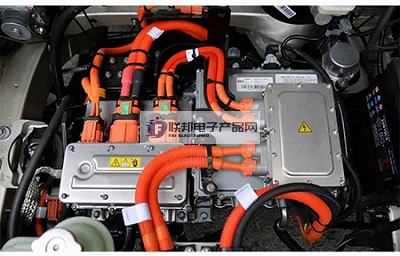

People are vulnerable in the presence of high voltages and a little inattention can kill them. Therefore, when carrying out repairs to the vehicle's high-voltage components, they can only be carried out in an uncharged state, i.e. by de-energizing the high-voltage system. Severe de-energizing operations include de-energizing (cutting off the main switch of the high-voltage system), strictly preventing the high-voltage switch from reclosing, and performing a power test operation (to ensure that the high-voltage system is not energized). High-voltage wiring harnesses, as the neural network of the high-voltage system, need to have a systematic understanding of them before maintenance. Compared with traditional fuel vehicles, the basic components of the high-voltage wiring harness of new energy vehicles are basically the same as those of traditional fuel vehicles. The difference mainly lies in the insulation performance, voltage resistance and self-shielding performance of the wiring harness.1. Voltage resistance: the rated voltage of buses is generally 600VAC/900VDC; ordinary buses generally use the rated voltage of 1000VAC/1500VDC, and its operating current is usually 250A, and some high-power motors can reach 400A.

2. Insulation: The insulation layer of the high-voltage wire harness should be tightly wrapped around the conductor and easily peeled off without damaging the conductor. The insulation layer should be in the water for 50Hz AC voltage test without being broken through. In addition there should be good resistance to high temperature, arc light, leakage traces and other properties.3. Self-shielding: high-voltage wire harnesses with shielding function of the cable, to avoid the self-generated electromagnetic interference on other components. Harness manufacturers use tinned copper mesh as a shielding layer, its density is not less than 85%, insulation resistance is greater than 500Ω/V, withstand voltage of 2500 volts, the operating temperature range between -40 ℃ ~ 125 ℃. All interfaces of the high-voltage wiring harness are shielded, the front and rear motor interfaces are shielded snap ring crimped to the battery box rail, and the controller and battery box plug-in are shielded structure. According to the standard requirements, the outer sheath of the cable adopts orange color, and the outer sheath of the positive and negative cable adopts plus red and black color identification. Qualified high-voltage wiring harness components include high-voltage cables, connectors, protective materials (insulation tubes, preparation tubes), sealing rings, tapes, heat-shrinkable tubes, labels and so on.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!