Categorization:Product Information

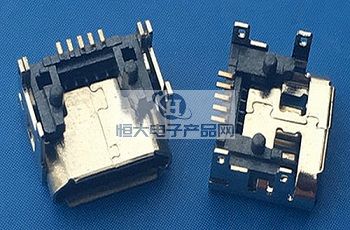

Conventional general operation in the MICRO USB female seat welding, please note that the pins are aligned with the pads on the various wiring points, after the need to use the iron to lightly press the pins, to be cooled for a few seconds, you can weld. But remember: such as in the Luo iron pressed usb female pins, pay attention to not squeeze too much strength, otherwise it will be its MICRO USB female interface pins welded through the situation. Then after practical experience in the operation of a few operational details: 1. Generally due to the MICRO USB bus interface pin more, and pin pin the longer the pin, the smaller the compression resistance, so in the usb bus interface storage, please do not use some heavy objects to squeeze the product to avoid causing damage to the usb bus for please teach the situation. And for the MICRO USB busbar packaging is recommended in general with packaging, because this can be avoided in the welding operation to take and put some fall and cause damage to the pins. 2.Secondly, there is a micro-USB busbar welding, please pay attention to the micro-USB busbar packaging tube will not be poured out all at once, in the material and did not pay attention to the strength of the products, products Squeeze each other, resulting in individual pin force bending, unevenness in the pad, resulting in the welding of false soldering false soldering may occur. 3. micro-USB female base of the bottom of the plastic positioning column, it is very easy in some routine improper operation and lead to the emergence of the position of the problem of offset, especially in some of the use of the machine mounted, generally in the welding, please pay more attention to the usb female base of the plastic positioning pillar Whether the welding position is correct, please before welding, otherwise the rear once welded stable, it is difficult to change the position of the usb busbar adjustments. 4. in the person usually in the manual welding, pay attention to the micro-USB busbar to the PCB circuit board pads, it is understood that many of the users found in the routine of the way in the pendulum plate will lead to micro-USB busbar connector interfaces out of the mouth of the mounter. Interface overall deviation, the USB female 5 pin pin can not correspond to the pad, so the rear caused by the function or short circuit of the hidden danger of the situation. 5. MICRO usb female soldering before the general attention to flux coated with solder pins, but remember not to stick too much flux, otherwise it is difficult to erase the latter. Because the role of the flux in addition to making the welding smoother, but also can fix the USB port welding is not easy to shift. After there is also about the small size of the USB female connector, in the USB interface pins are generally more difficult to weld, the key to weld if the distance between the pins is too close, accidentally will be two pins welded together.

-6, on the Evergrande electronic products network platform related to the introduction and sales of products briefly: Evergrande electronic products network - a professional agent / production / sales of all kinds of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] procurement / purchasing needs or would like to buy / to understand which connectors | harness | wire and cable products we can provide solutions, please contact the following Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!

-6, on the Evergrande electronic products network platform related to the introduction and sales of products briefly: Evergrande electronic products network - a professional agent / production / sales of all kinds of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] procurement / purchasing needs or would like to buy / to understand which connectors | harness | wire and cable products we can provide solutions, please contact the following Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!