Categorization:Product Information

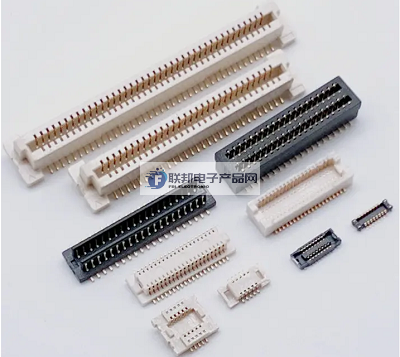

Since the board-to-board connector has more pins, each connection will wear out the pin alignment inside the interface, so avoid plugging and unplugging the connector too often, otherwise it will affect the board-to-board connection. Board connector life. Moreover, after the board-to-board connector is installed, generally for safety reasons, the connector can not be used immediately, you must test the quality of the weld. So do you know how to use and troubleshoot welding hazards?

1, in the selection of HRS board-to-board connectors, both high and low temperature resistance excellent performance, but also has the ability to resist impact and extrusion. As the use of the connector is not fixed, many devices must be used in special occasions; if the connector does not have these operating features, the use of the connector is generally relatively simple damage. 2, you can not scrape the board-to-board connection of the pin side of the metal plate, otherwise, once the scrape, it will lead to the impact of the connector's working function and service life, the use of the connector in the process may cause some data transmission Abnormal. 3, board-to-board connector before use, pay attention to check whether the connector is poorly connected or completely locked, so as not to use the connector in the use of simple malfunctions. 4, due to the use of HRS board connector for a long time, inside will accumulate some dust or other small debris, so when dealing with these issues, pay attention to the use of general silk cloth dipped in water to wipe, so that the electronic connector inside some of the other components 5, the choice of HRS board-to-board connectors must have excellent resistance to high and low temperatures, as well as resistance to impact and extrusion. As the connector is not fixed, many devices must be used in special occasions. If the connector does not have these operating features, the connector is generally easier to damage the use of the connector. Elimination of safety hazards method I: ordinary board-to-board connectors welding inspection is carried out through the welding of its solder joints to check, usually in the solder and solder substrate between the presence of obvious contours of the separation line, and in the printed circuit board pads at the end of the dimensions of the dimensions become smaller. Thus, it is judged that there is no influence of abnormal factors on the welding quality of the board joints. Elimination of safety hazards method two: because the board-to-board connector welding, generally unable to visually observe the quality of the connector's solder joints. Therefore, it is necessary to use a traditional X-ray flaw detector to test the board-to-board connectors on each module. Test results show that if the shape of the solder joints on the connector is the same, it can be proved that the connector welding quality is not very good, and the board-to-board connector part of the solder joints solder spacing is not equal, that is, it can be judged to be whether or not the occurrence of the impact of the offset and so on.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!