Categorization:Product Information

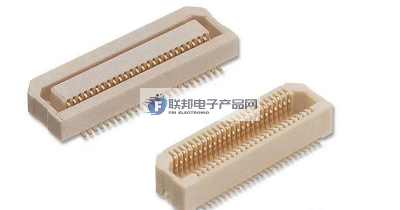

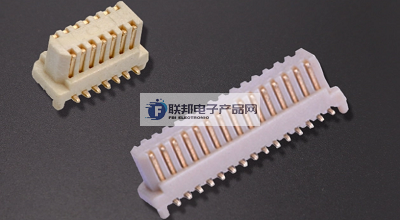

How can board-to-board connectors reduce jack and pin wear? From the perspective of today's connector market, the background and driver of the increasingly widespread use of board-to-board connectors are two major trends in the wireless device market: smaller size and lower price. As seen in the wireless terminal market, smaller, lighter, cheaper, but also the trend of the wireless device market; here we look at the basic applications of board-to-board connectors and how to reduce the wear and tear of jacks and pins.

Reducing the size of the device means that space can be saved, weight can be reduced, and more room can be left for the rest of the system's design. As device size continues to shrink, all integrations and dimensions in the device become smaller and smaller. This also includes RF coaxial connectors and their cable assemblies, which are widely used in RF modules and their interconnects. For example, RRH is widely used in distributed base station systems. For simple, easy and reliable installation on top of towers and in dense urban environments, their design has to be very compact and their dimensions have to be controlled as much as possible. The coaxial interconnect system that carries its RF signal transmission is also required to be more compact. A simple, compact and reliable "board-to-board" coaxial connector connection, which can simultaneously carry more than 100W of RF signal power, replaces the traditional complex cable assembly connection. Today, more and more RF and structural design engineers on the board-to-board connector knowledge more and more in-depth and in-depth, more and more designs began to use the board-to-board connector connectors, which also increases the cost of designers on the board-to-board connector requirements. Mechanical structure design challenges are mainly manifested in two aspects: First, compared with large-size connectors, small-size connectors are more difficult to locate; Second, the mechanical strength of small-size connectors is low, such as the use of improper is easy to be damaged; ordinary large connectors in the insertion and mating can withstand a greater mechanical force without damage, while small connectors in the insertion and mating need to be more accurate. How to reduce the jack, pin wear: 1, the thicker the nickel layer, the stronger the wear resistance of the gold-plated layer. 2, the smoother the surface, the lower the surface roughness, the lower the friction. 3, in the way of the board-to-board connector to pay special attention to the maintenance of the electrical board connector, to reduce the man-made damage caused by the electrical board-to-board connector.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!