Categorization:Product Information

The wiring harness manufacturing process is time-consuming, difficult and task-oriented. Nonetheless, as the demand for wire harnesses and cable assemblies grows, so does the manufacturing of these components. That's because wiring harnesses are one of the most indispensable electronic and electrical components in the modern world!

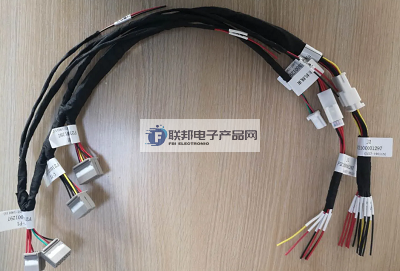

STEP 1: DESIGNING THE WIRE HARNESS Whether hidden behind the glove compartment of a car or inside the back panel of a washing machine, the wire harness provides power and transmits information in a streamlined, uniform manner. In electronics development, engineers must face and overcome electrical problems on a daily basis in order to bring products to market successfully. An integral part of this challenge requires a customized design for each product's electronic components, as well as a step-by-step harness manufacturing process to complete the assembly. This is also the stage where the engineer must select the harness components and decide on other specifications for use. Step 2: Prototyping If necessary, wire harness prototyping allows engineers or product designers to obtain a realistic version of the final product. They can then test the harness in its intended application to ensure better performance before starting a sub-production run. Step 3: Manufacture and Assemble the Harness Manual Assembly In harness manufacturing, design specifications must be met and high quality standards must be maintained with minimal error rates. It is important to note that in this day and age, with automated manufacturing expanding globally in almost every field, the wiring harness manufacturing process still relies heavily on manual assembly. While some automation can be added to the process, wire harnesses and cable assemblies must be manufactured by hand due to the many complex and time-consuming steps involved in completing the process. While building wire harnesses can be difficult and task-oriented, manual production is still more cost-effective. Another reason hand production remains the primary method of manufacturing wire harnesses and cable assemblies is that they must be customized for each application. Wire harnesses are very specialized assemblies designed for specific larger parts. They need to solve geometric and electrical problems in the manufactured product and provide solutions to specific problems inherent in the overall process. Geometrically, wire harnesses are designed to fit in a specific space within or next to a larger network of electronic components and wiring. Wire harnesses must also be grounded and protect wires from potential internal and external damage associated with electrical problems, such as crossed wires, chemicals, or moisture. Wire CuttingBroadly speaking, the step in building a wire harness is to ensure that the wires are cut to the correct length, which is done by a wire cutter. Stripping and ConnectingThe next step requires that the ends of the wires must be stripped to expose the core wires. This is done in order to next connect the terminals or connector housings or modules. Finally, the wires are gathered into a wire harness utilizing a workbench or assembly board to meet the design specifications. Hand fabrication for harness production is necessary to run the wires through the sleeves and apply fabric tape where needed, such as on the branches of the harness. Terminals need to be crimped to the wires, or multiple times if more than one wire needs to be connected to a terminal. In addition, inserting one sleeve into another is done manually, so secure any strands with tape, clips or cable ties. Wire Processing Machines Manual production does not preclude the use of automation and machinery in wire harness manufacturing. Cutting machines are used to cut wires uniformly into specified lengths, and machines are used to crimp terminals or insert wire sections with appropriate terminals into connector modules. Soldering machines are necessary to seal the ends of wires, as are tools for twisting wires. After production is complete, each individual harness must be tested for electrical safety against any specifications to which it may be subjected in actual operation. This step is critical to ensuring that the final product operates reliably. Harness manufacturing is a process. The design and assembly of a harness from drawing board to finished product requires step-by-step planning and a great deal of hand production. Each harness has a specific purpose and can be integrated into a larger electronic network, which really makes them indispensable in the modern world.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!