Categorization:Product Information

Along with the rapid development of electronic devices, automobiles and other electronic technologies, the market demand for wiring harnesses continues to grow, but also for miniaturization, lightweight and other features and quality requirements. Huicheng Yuan wiring harness supplier will introduce you to the necessary appearance inspection items to guarantee the quality of wiring harness. We will also introduce the application cases of using new 4K digital microscope system to realize magnified observation, measurement, inspection, quantitative evaluation and improvement of operation efficiency.

Wiring harnesses, which have grown in importance and demand at the same time, are also known as cable harnesses, and are components that are formed by bundling multiple electrical connections (power supply, signaling, and communication) wiring needed to connect electronic devices into a bundle. By utilizing a connector that integrates multiple points of contact, it is possible to simplify connections while preventing misconnections. In automobiles, for example, 500 to 1,500 wiring harnesses are used in a single vehicle, and these harnesses can play a role equivalent to that of human blood vessels and nerves. Defective or broken wire harnesses can have a significant impact on product quality, performance and safety. In recent years, motor products and electronic devices have shown a trend of miniaturization and high density, while in the automotive field, EV (electric vehicle), HEV (hybrid electric vehicle), driver assistance functions based on induction technology and automated driving and other technologies are also developing rapidly. Against this backdrop, market demand for wiring harnesses continues to grow, and in terms of product research and development and manufacturing, we have entered a new era in which we are striving to satisfy a wide range of needs by pursuing a wider variety of products, miniaturization, lightweighting, high functionality, high durability, and so on. In order to meet these needs and to provide new and improved products of high quality quickly, it is necessary to meet higher requirements for accuracy and speed in the evaluation of research and development, and in the inspection of the appearance of the manufacturing process. Terminal Connection and Appearance Inspection of Wires, the Key to Quality In the manufacturing process of wire harnesses, before assembling components such as connectors, tubes, guards, clips, clamps, etc., an important process that determines the quality of the harnesses is the connection of the terminals of the wires. When connecting the terminals, we use the processes of "crimping (convergence)", "pressure welding", and "soldering". When using various connection methods, once the connection is abnormal, it may lead to poor conductivity, core wire off and other faults. There are many ways to check the quality of wiring harnesses, such as using a "wiring harness tester" (conductivity tester) to check for electrical breaks, short circuits, etc. However, it is important to check the quality of wiring harnesses after all types of tests and after all types of tests. However, in order to examine the exact state and cause of the problem after various tests and at the time of the failure, it is necessary to inspect and evaluate the appearance of the terminal connections with the aid of a microscope and the magnifying function of a microscope system. The following is a list of inspection items for each connection method. The appearance of crimping (seam) is examined by crimping the cable to the sheath using the plasticity of the copper cladding on the conductor of each type of terminal. The conductor copper is bent through the "seam" using a tool or automated equipment on the production line.

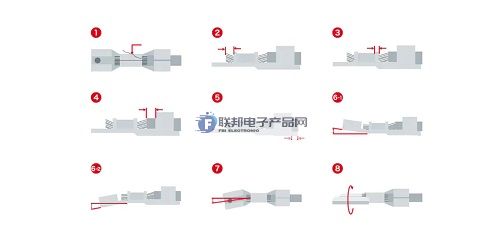

[Appearance Inspection Program]

| (1) Core wire protrusion | (2) Core wire protrusion length | (3) Flare volume | (4) Sheath protrusion length |

| (5) Cutting length | (6)-1 upward bending/(6)-2 downward bending | (7) Rotation | (8) Shaking |

Crimped terminals convergence seam quality judgment benchmark "crimp height" after the completion of terminal crimping (convergence seam), cable and jacket convergence seam at the height of the conductor copper cross-section, is the "crimp height". Failure to make a seam according to the specified crimp height may result in poor electrical conductivity or cable detachment.

A crimp height higher than the specified value will result in an "under crimp" and the wire will come loose under tension. Below the specified value will lead to "over crimping", the conductor copper will be strangled into the core wire, resulting in damage to the core wire. The crimp height is only a judgment benchmark for inferring the condition of the sheath and core wire. In recent years, with the miniaturization of wiring harnesses and the diversification of materials used, quantitative core wire condition testing of crimped terminal sections has become an important technology to detect all types of defects in the convergence process.

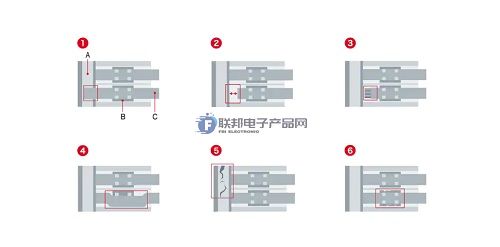

Appearance Inspection Program for Pressure Welding A wire with a sheath attached is inserted into the slit so that it is connected to the terminal. When the wire is inserted, the sheath comes into contact with the knife blade fitted to the slit and is pierced, creating electrical conductivity and eliminating the need to strip the sheath. [Appearance Inspection Items] (1) Excessive length of wires (2) Gaps at the top of wires (3) Protrusion of conductors before and after the crimp sheet (4) Crimp center offset (5) Defects in the outer casing (6) Defects and deformations in the crimp sheet A: outer casing B: crimp sheet C: wires

Appearance of soldering inspection program representative of the terminal shape and cable routing method can be divided into "tin groove type" and "round hole type", the former will be passed through the wire from the terminal, the latter will be passed through the cable from the hole. [Appearance Inspection Items] (1) Protruding core wires (2) Poor conductivity of solder (insufficient heating) (3) Bridging of solder (too much solder)

Application Example of Wire Harness Appearance Inspection and Evaluation With the miniaturization of wire harnesses, appearance inspection and evaluation based on magnified observation is becoming increasingly difficult. Keenshi's ultra-fine 4K digital microscope system realizes high-level magnified observation, visual inspection, and evaluation while dramatically improving work efficiency. The VHX series of 4K digital microscopes utilizes a "navigation real-time compositing" function to automatically perform depth compositing on three-dimensional objects, making it difficult to conduct comprehensive observation and evaluation of the target as a whole, since it is a three-dimensional object that can only be partially focused. The VHX Series 4K digital microscopes utilize the "navigation real-time compositing" function to automatically perform in-depth compositing and capture ultra-high-definition 4K images that focus on the target as a whole, making it easy to carry out correct and efficient magnified observation, appearance inspection, and evaluation.

When measuring warpage of wire harnesses, not only do you have to use a microscope, but you also have to use a variety of other measuring instruments, which makes the measurement process cumbersome and time-consuming. In addition, it is not possible to record the measured values directly into data, which is a problem in terms of operational efficiency and reliability. 4K digital microscope system "VHX series" is equipped with a variety of tools for "2D dimensional measurement", and measures the angle of the wire harness, The VHX Series is equipped with a variety of tools for "2D dimensional measurement," which enables measurement of various data, such as the angle of a wire harness and the crimp height of a crimp terminal cross-section, in a simple operation. With the VHX Series, not only can quantitative measurements be made, but data such as images, values, and shooting conditions can also be saved and managed, making it possible to improve work efficiency by leaps and bounds. After saving the data, you can select previous images from the photo album and carry out additional measurements at different locations and for different projects.

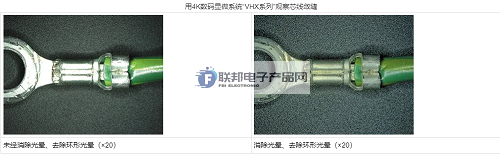

The VHX series of 4K digital microscopes is equipped with halo removal and ring halo removal functions, which make it possible to correctly observe and grasp the status of the core wire's convergence seam, which is unaffected by the luster of the metal surface, and which is affected by reflections from the metal surface. The VHX Series 4K digital microscopes are equipped with "Halation Removal" and "Ring Removal" functions, which allow you to correctly observe and grasp the seam condition of core wires by eliminating the reflection interference caused by the luster of metal surfaces.

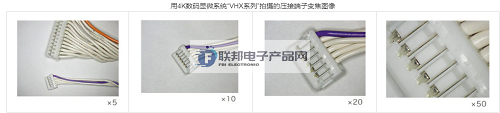

Have you ever experienced the difficulty of accurately focusing on small, three-dimensional objects such as wire harness seams during exterior inspection, which makes it difficult to observe small parts and fine scratches? The VHX Series 4K digital microscope is equipped with a motorized lens converter and a high-resolution HR lens, which enables automatic magnification conversion from 20 to 6,000 times, realizing "seamless zoom". The VHX Series allows you to zoom in and out quickly with a simple operation using a mouse or a controller at hand.

Omni-directional observation system that realizes efficient observation of three-dimensional objects When observing the appearance of three-dimensional products such as wire harnesses, it is necessary to repeat the operation of changing the angle of the target object and then fixing it, and to focus on each angle separately. The VHX Series of 4K digital microscopes utilizes an "omni-directional observation system" and a "high-precision X, Y, and Z motorized stage," making it possible for some microscopes to observe a wide range of objects in an efficient manner. "The VHX Series supports flexible movements of the sensor head and stage that are not possible with some microscopes. An adjustment device that allows easy adjustment of three axes (field of view, rotation axis, and tilt axis) enables observation from all angles. Moreover, even when tilted or rotated, the target object does not jump out of the field of view and remains in the center, thus dramatically improving the efficiency of observing the appearance of three-dimensional objects.

3D Shape Analysis for Quantitative Evaluation of Crimped Terminals When observing the appearance of crimped terminals, not only is it necessary to focus on the three-dimensional target by area, but there are also problems such as missing anomalies and human evaluation deviations. The VHX series of 4K digital microscopes can not only perform magnified observation and 2D dimensional measurement with clear 4K images, but also capture 3D shapes, perform 3D dimensional measurement, and measure the contour of each cross-section. The VHX Series enables analysis and measurement of 3D shapes by simple operation without requiring the user's proficiency, and at the same time realizes a high degree of sophistication and quantification in evaluating the appearance of crimped terminals, as well as efficient operations.

Automatic Measurement of Slit Cable Sections The 4K digital microscope "VHX Series" utilizes a wide range of measurement tools to perform automatic measurement of various types using captured section images. For example, as shown in the figure below, it is possible to automatically measure only the area of the core wire portion of the core wire seam cross-section. These functions enable quick and quantitative inspection of the condition of the core wire in the seam section, which cannot be grasped by crimp height measurement or cross-section observation alone.

New tools for rapid response to market demand In the future, the market demand for wiring harnesses will increase, Huicheng Yuan wiring harness suppliers in order to meet the rising market requirements, must be based on fast and accurate test data, to establish a new research and development, quality improvement mode and manufacturing processes.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!