Categorization:Product Information

Harness processing plant belongs to labor-intensive enterprises, a few days ago the rising cost of labor, resulting in harness processing plant profits continue to decline, in order to better adapt to the development of the industry, the continuous introduction of advanced production equipment to enhance production efficiency at the same time, the harness workshop process management to improve the essential aspects of the process, then how to effectively harness processing plant process control it?

Process control is one of the direct guarantee of quality assurance, Hua Chen Yu wire harness processing plant for better management of process control, and ultimately meet customer requirements for products, engineering, materials, quality and production classes of several departments to work together, cooperate with each other, mainly from the following four aspects of effective process control: First, drawings, sample production and production process tracking. 1, engineering to retain the customer's drawings and convert Hua Chen Yu internal drawings to ensure the consistency and correctness of the drawings. 2, wire harness processing products in the sample preparation process throughout the process of process design and man-hour design reasonableness. 3, in the small batch production process, throughout the process of monitoring the real-time data in the processing of the wire harness to find out if there is a problem in the processing of the wire harness in a timely manner and solve it in a timely manner. Second, wire harness processing plant raw material procurement and scheduling 1, PMC according to the order to arrange production orders to, monitor the production of materials, and organize the application for the purchase of materials required for production. 2, PMC follow up production orders to prepare the "production plan", according to the production situation and changes in the material, changes and adjustments to the production plan, according to the delivery of online production orders emergency communication and coordination of the production plan. Third, wire harness processing quality control 1, IQC must be in the material into the factory in strict accordance with the parts drawings for inspection. 2, quality control in the production process, batch failure quality inspection and critical process control, the first batch of inspection and sampling inspection of mass production. Fourth, harness processing plant production monitoring 1, "5S" management in the harness processing production site is strictly enforced. 2, according to the "production plan" for production task scheduling, strict implementation of the "Production Plan" and "Transfer Instructions" control. 3, each workstation must be in the online beam processing production process of self-checking, IPQC process inspection and fill in the report in a timely manner and provide abnormalities in the production process. and fill in the report in time, and provide abnormal and timely feedback.

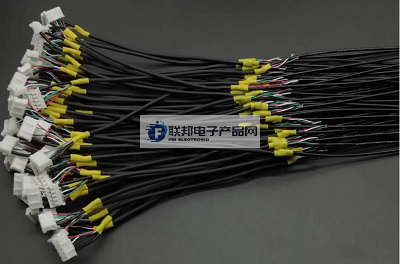

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!