Categorization:Product Information

In the field of wiring harness processing, the quality of wiring harness products has become the core of the various large and small enterprises are necessary to master, wiring harness is used in many industries, it helps in various professions is very large, in order to be the frontrunner from a lot of enterprises, will not let go of the quality of ensuring this important element of competition. In order to ensure the quality of wire harness products together, but also the quality of service, and strive to achieve production, service quality double optimization. So how to ensure the quality of wiring harness processing factory wiring harness processing? The following Huicheng yuan electronic editorial to introduce to you. Harness processing plant how to ensure the quality of wiring harness processing: First, the details of wiring harness processing to determine the quality of the harness 1, wire tin / tin need to manipulate the time wire stripping, once the wire dipped in tin, too long a period of time may cause the PVC heat shrinkage, so to manipulate the tin dip / tin time is not too long, together with to ensure that the tin dip evenly and completely covered.

2, wear rubber shells, pay attention to the terminal off PIN in wearing rubber shells often occur when the terminal off PIN, harness processing process, the need for each inserted into a hole when there is a pull back action, to ensure that each through the rubber shell of the terminal is good. 3, crimp to ensure that the tension is enough crimping, if the tension can not be reached, the need to check the crimp scale of the terminal and the wire conductor is suitable; Mold blade material and its structure of the design is reasonable; terminal material is qualified and so on. Second, the harness processing testing process to ensure that the quality of the harness 1, wire processing manufacturer said that the production process, each link needs to have a standard testing process, manual testing + machine testing, as long as each link is a good quality test to ensure the quality of production and processing of wire harnesses. 2, the finished line needs to be done to shake, hanging weight, and conductivity tests and so on. General shaking test conditions: shaking frequency, hanging load and shaking requirements of Z fewer times and other parameters. Lifting test conditions to have: lifting load, lifting time and lifting after the displacement size of these three parameters. The above content is how to ensure the quality of the harness processing plant wiring harness processing is introduced, wiring harness processing of the production process of wiring harness products and functional inspection of the appearance of the inspection of the arrangement of the workstation, the selection of detection and measurement methods can be effective to a certain extent to ensure that its wiring harness processing to do a good job in all aspects of the operation, manipulate the quality of the production from the source to improve the processing of wiring harnesses failure to do a good job of the real high efficiency, High-quality production, so that the quality of the wiring harness products produced to meet customer requirements.

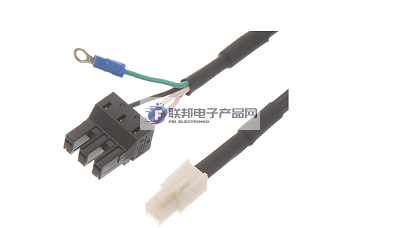

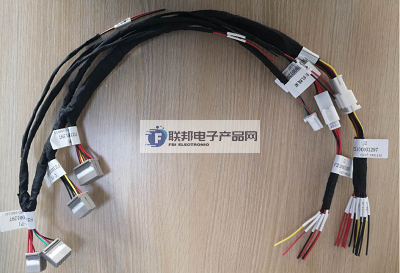

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!