Categorization:Product Information

With the rapid development of China's 5G field, home appliance field, automotive field, industrial computerization and the market, the importance of the electrical wiring industry is becoming more and more obvious. From the point of view of domestic wiring harness development, China's wiring harness processing costs are low. Most of the wiring harness processing plant directly based on customer drawings for conversion production, the lack of their own wiring harness design. But there is no lack of production and design integration of wire harness processing plant today's wire harness processing plant briefly introduce the material design principles of wire harness processing plant. Wire harness processing plant material design principles should be analyzed from the center line of the wire and the outer line, as follows: 1, the structure of the wire outer sheath material. The outer sheath of the wire is mainly made of PVC, PU, PE materials, which are characterized as follows: PVC (thermoplastic polyvinyl chloride) characteristics: PVC is used in the temperature range of -55105, with excellent flame retardant, wear-resistant molecular structure. It is not easily corroded by organic solvents, acids and alkalis, and has good non-migration properties. Since PVC is odorless, tasteless, and non-toxic, it can be used in physical and medical applications.PVC's high dielectric constant exhibits high capacity and low attenuation, making it suitable for use in electronic wiring and data lines.PVC's low elasticity prevents it from being well suited for use in flexible wires. PVC becomes brittle at low temperatures. This means that when wires still need to be very soft at low temperatures, PVC should be left out as much as possible. PVC is used for the outer insulation of insulated data wires and as a material for electronic wiring.2. Characteristics of PE (polyethylene): It has good electrical characteristics and is widely used in coaxial wires and data cables that require low capacitance of the wire. Although PE is flammable, we can add flame retardants to it. Of course, this will slightly increase the dielectric constant. And it will increase the energy attenuation. 3. PU (Polyurethane): At low temperatures, PU is still very soft and has high tensile strength and bending life. PU has good water resistance, chemical resistance, abrasion resistance, but also has good tear resistance. 4. TEFLON TEP (Teflon TFE): The current price of Teflon is 612 times higher than that of good PVC. TFE has excellent dielectric constant, not only stable but also small coefficient. In addition, TFE is a thermosetting material, which makes it possible to use it on iron (e.g., ro soldering iron) without damage. Second, the composition of the raw materials of the wire core. The cable mainly communicates through the outer sheath and conductor. Select the outer sheath according to the customer's use of environmental temperature, according to the current and voltage requirements under different electrical requirements to choose the conductor structure. The conductor of the wire mainly includes: bare copper wire, tinned copper wire, In short, the material and performance of the cable directly affect the role of the product in the use of the environment. Therefore, wire harness processing plant for customers in the design of wire harness, must be designed before the use of products to understand the environment and electrical performance. In order to meet customer needs, Longman Electronics is committed to wire harness processing plant, which is mainly used for the technical development of electronic products, such as wire harness processing intelligent, connecting cable processing, data cable processing and so on. We have complete technical experience, integrating R&D, design, manufacturing and sales marketing system, advanced production equipment and quality assurance capabilities.

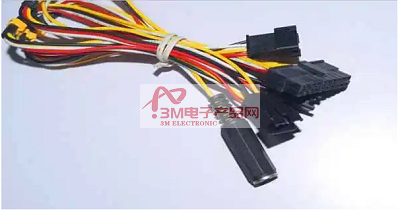

Wire Harness Processing Factory The quality of the wire harness material directly affects the quality of the wire harness, and the choice of the wire harness material is related to the quality and service life of the wire harness. When choosing products, you must not be greedy for cheap. Cheap wiring harness products may be inferior wiring harness materials. How to recognize the quality of the wiring harness? Understand the material of the wiring harness, you will understand. The following materials are used for wiring harness selection. Wiring harnesses generally consist of wires, insulating jackets, terminal blocks, and wrapping materials. As long as you know these materials, you can easily determine whether the wiring harness is good or bad. First, the terminal material selection terminal material (copper parts) used in the copper is mainly brass and bronze (brass is slightly lower than the hardness of bronze), of which brass has a greater specific gravity. Otherwise, different coatings can be selected according to different requirements. Second, the choice of insulation sheath sheath material (plastic parts) commonly used materials are mainly PA6, PA66, ABS, PBT, pp and so on. According to the actual situation, you can add flame retardant or reinforcing materials in the plastic to achieve the purpose of enhancement or flame retardant, such as adding glass fiber enhancement. Third, the choice of wire harness conductor according to different applications, select the appropriate wire. Fourth, the choice of dressing materials harness dressings play a wear-resistant, flame retardant, anti-corrosion, anti-disturbance, noise reduction, landscaping role. Generally according to the working environment and the size of the space to choose the dressing material. There are generally tape, bellows, PVC pipe, etc.. In the choice of dressing materials.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a related [connectors | wiring harness | wire and cable products] sales / resources and promotion needs, please click "→ Business Cooperation ← with a dedicated person to discuss! If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!