Categorization:Product Information

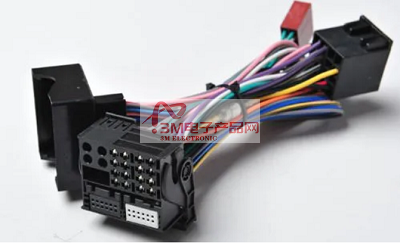

With the increase in wages and recruitment difficulties, many factories are now unable to meet the production needs by hand, so many wire harness production and processing plants choose to outsource manual to solve this problem. So what problems should be noted in the process of sending out? Here is a brief introduction.1. Training for manual workers to ensure that workers know what position the rubber housing, the position should correspond to the good, can not fall off.2. After the completion of the wiring harness production and processing, you need to check the quality of the product. If unqualified products are found, they need to be returned and reworked before reshipping.3. Stripping: first check whether the machine and blade are normal, and whether the table is clean, and then stripping.4. Riveting the terminals: pay attention to whether the riveting tension is in accordance with the requirements, and don't allow flying wires or deformation of the terminals.5. Assembling the rubber casing: after the above work is completed, place it in the same direction as the casing fixture and fix it.6. Testing, checking whether the energized, short-circuit and leakage, etc. 7.The package can be shipped from the warehouse, the quality of the package is the key. If the quality cannot be guaranteed, please consider outsourcing carefully. Wire harness production and processing, including its electrical properties, material launch, temperature resistance, etc.. are higher than the general wiring harness requirements, especially when it comes to safety: for example, the important parts of the harness such as the direction control system and brakes, which requires more stringent wiring harness production processing. Harness production and processing standards depend mainly on the calculation of its crimp rate, which requires a special instrument, the factory developed a standard tester for wire harness cross-section, electronic wire harness is specifically designed to detect whether the wire harness crimping qualified tester. Mainly through the steps of cutting, polishing, corrosion, observation, measurement and calculation, the whole operation can be completed in only 5 minutes.

Terminal harness processing may appear in a lot of bad problems, usually due to bad factors or improper operation methods lead to poor processing of terminal harness. Regarding the terminal harness processing problems, the following Huicheng Yuan wire harness processing factory mainly explains in detail the common error problems in the processing of terminal harnesses.1. The terminal pins of the terminal line are coated with glue, which leads to the failure of the product power failure short circuit.2. Air compression occurs at the end of the terminals of the terminal line, which leads to the leakage or poor contact and other malfunctions.3. Improperly assembled terminals of the terminal line and the rubber casing, which leads to abnormal separation of the terminals from the plugs and the plugs. The main reason for these factors is that the processing details are not handled properly, but in fact many of them can be avoided. In response to these problems, the terminal wire harness processing plant and shared by everyone has some small knowledge 1. Terminal wire processing with wire tinning needs to be accurately controlled. Once the wire is tinned after stripping, if the heating time is too long, the PVC may be heated and retracted. Therefore, the tinning time should be controlled so that it is not too long, and the tinning should cover evenly. 2. When the terminal wire passes through the rubber housing, pay attention to the removal of the terminal PIN. Since terminal PIN removal sometimes often occurs in the rubber casing, the terminal wire needs to be pulled back each time it is inserted into the hole during the processing of the terminal wire to ensure that each terminal that passes through the rubber casing is a good product.3. After crimping, you should make sure that the tension of the terminal wire is maintained. If the tension after crimping is not up to standard, you need to check whether the crimping scale of the terminals and wires is appropriate, whether the raw materials and structure planning of the mold blade are reasonable, and whether the raw materials of the terminals are qualified.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a related [connectors | wiring harness | wire and cable products] sales / resources and promotion needs, please click "→ Business Cooperation ← with a dedicated person to discuss! If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!