Categorization:Product Information

The development of row mother in our country is still very rapid, the general volume is relatively small. Because the row of mother itself is very small, so the production requirements of the row of mother is very fine, the following will tell you about the process of making the row of mother:

Take material and burr according to the specified length size. Tin lining according to the lap requirements of the row mother, the copper mother row with back wire wipe clean, and after immersed in a solution of zinc chloride for about 3 to 5 minutes.

Remove the busbar and remove the tin particles on its surface with a brush, then cool it, then clean and dry it. Bend the busbar according to the direction of busbar alignment, busbar bending needs to be based on the provisions of the general recently insulated busbar support plywood edge to be less than 0.25L.

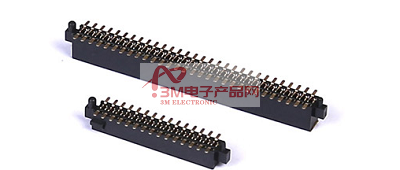

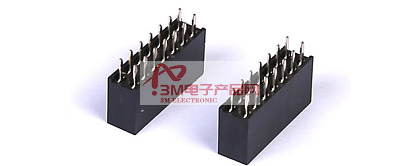

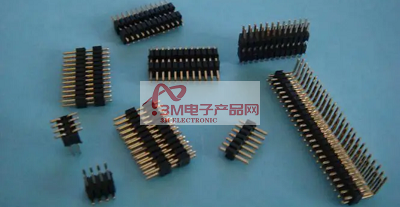

Application: smart meters, meters, carriers, UPS, inverters, car recorders, car alarms, network switches, routers, laptops, computers, MID, digital cameras, boards, and smart communication products, smart home appliances and other products. The role of the row of pins: its role is to be blocked in the circuit or isolated between the circuit, play the function of the bridge, take up the task of current or signal transmission set of tasks to make. Usually used with the mother, constitute a board-to-board connection; or with the electronic harness end supporting the use, constitute a board-to-line connection; can also be used independently for board-to-board connection. Pin classification and types: 1, pin row according to the pitch division: 0.8mm, 1.0mm, 1.27mm, 2.0mm, 2.54mm pitch. 2, according to the height of the plastic and the number of plastic division (such as single-plastic, double-plastic, 3 plastic, etc.) 3, according to the number of rows of pin rows are divided into: single-row, double-row, 3 rows, 4 rows, etc., 4, according to the way of installation is divided into: 180 degrees, S. 90 degrees, R. SMT, SMT, SMT, SMT, S for 180 degrees, R for 90 degrees, and M for SMT. Packing method of pins: bag, tube, roll. Pin material: pin material: brass or phosphor bronze; insulator material: plastic UL 94V-0. Surface treatment: gold-plated 0.8u, tin-plated, nickel-plated pins of the specific parameters, the material number within the explanation: 1. number of rows: single-row, double-row can be selected. 2. number of PINs: 1-100P. 3. soldering method: straight, curved, SMT; pin size. 4. size: external dimensions of length, width, thickness, spacing, etc. 5. Pitch: 0.8mm, 1.0mm, 1.27mm, 2.0mm, 2.54mm.

2、About 3M electronic products network platform related to the introduction and sales of products briefly: 3M electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!