Categorization:Product Information

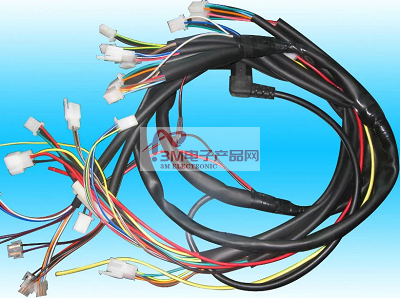

In modern automobiles, there are many automobile electric bicycle wiring harnesses, electronic control systems and wiring harnesses are closely related. Some people have made a graphic analogy: if the function of microcomputers, sensors and actuators compared with the human body, it can be said that the microcomputer is equivalent to the human brain, the sensor is equivalent to the sensory organs, the actuator is equivalent to the motor tubes, then the electric bicycle wiring harness is the nerves and blood vessels. The electric bicycle wiring harness is the main network of the automobile circuit, connecting the electrical and electronic components of the car and making it work. No wiring harness, no automobile circuit. At present, whether it is a luxury car or an economical ordinary car, the wiring harness is basically the same form, consisting of wires, connectors, packaging tape. To ensure the transmission of electrical signals and the reliability of the connected circuits, to provide electronic and electrical components with a specified value of current, to prevent electromagnetic interference with the surrounding circuits, and to reduce the occurrence of electrical short circuits.

Functionally, there are two types of electric bicycle wiring harnesses: power wires that carry power to drive actuators and signal wires that carry sensor input commands. Power wires are thick wires that carry high currents, and signal wires are thin wires that do not carry electricity (fiber optic communication); for example, signal circuits have conductor cross-sectional areas of 0.3 and 0.5 m2. Motor actuators have conductors with cross-sectional areas of 0.85 and 1.25 m2. power circuits have conductors with cross-sectional areas of 2, 3, and 5 m2. and special circuits (starter motors, alternators, engine grounding wires, etc.) are available in 8, 10, 15 and 20m different specifications. The larger the cross-sectional area of the conductor, the greater the current capacity. The selection of wires is limited by the physical properties of the vehicle in addition to the electrical properties, so its choice is wide. For example, soft wires are used for doors that are frequently opened and closed by cabs and for wires that run across the body of the vehicle. Conductors used in high temperature areas are generally vinyl chloride and polyethylene covered conductors with good insulation and heat resistance. In recent years, more and more electromagnetically shielded wires have been used for weak signal circuits. With the increased functionality of automobiles and the wide application of electronic control technology, there are more and more electrical components and wires in automobiles, the number of circuits and power consumption have increased dramatically, and the wiring harnesses have become thicker and heavier. This is a big problem that needs to be solved. How to more effectively and reasonably arrange a large number of wiring harnesses in the limited automobile space, so that the automobile wiring harness to play a greater role, has become a difficult problem facing the automobile manufacturing industry. For electric bicycle wiring harness processing, the important part is the online processing of wiring harness products. So we try to pay attention to the whole process. So how to improve the connection process of wire harness processing through this process to ensure the performance and quality of electric bicycle wire harness products? Electric bicycle wiring harness processing is mainly based on the circuit schematic. Therefore, the first thing to do is to design the circuit schematic, clarify the location of each electronic component and wiring, to achieve the standardization of wiring harness processing. and computerization. This also helps to improve the automation level of wire harness production, which can effectively improve the production efficiency of the wire harness. It also helps to improve the informationization level of electronic wire harness processing manufacturers. Through different ways to achieve a more perfect state of the wire harness connection technology, so as to give full play to the Z-best performance of the equipment. In general, in today's society, the connection technology of wire harness must be improved without the use of advanced technology such as computers. Structurally, the processing direction of the electric bicycle harness is similar. The cables need to be wrapped around an outer polyester film. This improves insulation and prevents oxidation of copper wires. It is necessary to control the strength of the insulating core around the encapsulation. The distance between the tape, the outer core of the cable sheath, the power core2 and the control core is small, and the structure is relatively strong and tight where there is no filler or padding. Avoid short circuit problems. First, the terminal line factory must take insulation measures; second, when connecting the power supply, be sure to carefully check whether there is a short circuit. It should be noted that the method of selecting the battery short-circuit checking equipment is point status. This is very unpopular and can easily cause accidents. When the electric bicycle wiring harness is short-circuited, the current will increase, and the heat generated will directly melt the joints of the wires. This will create a spark. If the situation is serious, it will cause an explosion. So the electric bicycle wiring harness processing plant and the user wiring harness processing plant should never underestimate the problem of wiring harness short circuit, and must take relevant precautions.

2, on the 3M electronic products network platform related to the introduction and sales of products brief: 3M electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!