Connector, also known as aviation plug, is an important functional component to complete the transfer and energy transmission. At present, they are widely used in new energy vehicles, aerospace, rail transportation, intelligent manufacturing, communications, computers, industry, household appliances and other fields. At present, the technology of new energy electric vehicle industry is becoming more and more mature, and the production and demand are also increasing. New energy vehicle connectors, as an important interconnection device in the car, play a key role in the automatic control system of diesel engine, automobile chassis and body, and electric vehicle electronic equipment. In recent years, the development prospects of connectors tend to be technical. But with the improvement of the application carrier technology, the various specifications of the connector is also slowly changing. For example, in the automotive connector market, new energy vehicles are more concerned. Because of the new energy vehicle's various technologies are advancing, especially the connector, not to mention a car with multiple connectors. In order to fully utilize the efficacy of new energy vehicles, scientific research and technology must be strengthened. The following Huicheng Yuan will analyze with you. What qualities do new energy vehicle connectors need to have in order to be competitive in the market?1. New energy vehicle connectors require energy saving. Green cars need to be equipped with components. Because new energy vehicles are green cars, so the connector also needs to be energy efficient. Whether it is the manufacture of components or practical applications, avoiding pollution and reducing energy consumption have become factors to be considered when factories produce connectors. These characteristics will also become a strong market advantage for the enterprise products.2. Reliability of new energy vehicle connectors. Due to the new energy vehicle connectors to withstand the upper limit of current and voltage capacity, the requirements of the anti-electrocution protection is obvious. At the same time, electromagnetic interference is another important issue under such high power. In addition, the plugging and unplugging operations of connectors can generate electric arcs, which can seriously jeopardize electrical connections and electronic equipment, and may lead to vehicle combustion. All of this requires connector design and development. For example, to prevent high voltage in the exposure of air breakdown, need to maintain the air gap; in the high voltage, high current conditions, the temperature rise can not exceed the rated value; in the selection of shell materials, we should consider the weight, strength and ease of processing, the connector terminal material properties how to maintain stability at different temperatures, and how to ensure electrical conductivity.3. New energy automotive connector durability. Very often, the car engine is usually placed in front of the car. Although there is a firewall protection, but there will be some heat transfer, in addition, the strict requirements for automotive connectors are also reflected in the service life. General connectors have elastic components, which will fail after the number of times of insertion and extraction. So a car's service life is generally about 3-5 years, while a car can be used for 10-20 years. So the service life of the automotive connector should be comparable to the car, which has high requirements for the connector.4. The connectivity of the new energy vehicle connector. With the continuous expansion of the vehicle system, the importance of high-speed data transmission function is increasingly prominent. For example, some models have cameras installed on the rearview mirror, which can give the driver a wider field of view, which requires a connector to transmit more data. Occasionally, a connector is needed to solve the problem of transmitting GPS signals and broadcasting signals, so it is necessary to improve its data transmission capability.

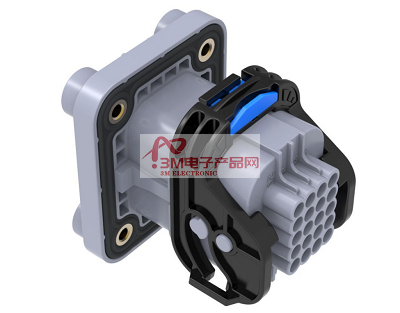

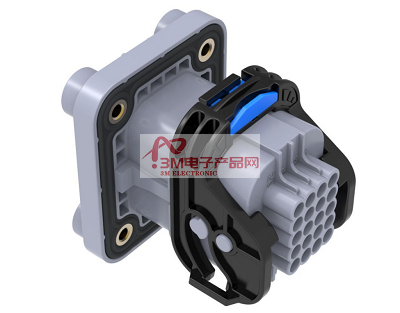

Characteristics and specifications of new energy vehicle connectors.1. Reliability of the connector: the future of new energy vehicle connectors will be able to withstand a current of 250A and a voltage of 60OV, the requirements of anti-electrocution are obvious. At the same time, in this high power, electromagnetic interference is also an important issue. In addition, the plugging and unplugging operation of the connector will generate arcs, which will seriously jeopardize the electrical connection and electronic equipment, and may lead to automobile combustion. All of this requires connector design and development. For example, to prevent high-voltage in the exposure to break through the air, the need to maintain air space; in the high-voltage, high-current conditions, the temperature rise can not exceed the rated value; in the selection of shell materials, take into account the weight, strength, and ease of processing, the connector terminals of the material performance how to maintain stability at different temperatures, and how to ensure electrical conductivity.2. Diversification of connector functions:With the continuous expansion of the automotive entertainment system, high-speed The importance of the data transmission function is increasingly prominent. For example, some models are installed in the rearview mirror camera, which can give the driver a broader field of vision, which requires a connector to transmit more data. Sometimes a connector is needed to solve the problem of transmitting GPS signals and broadcasting signals, so it is necessary to improve its data transmission capability.3. Ability to adapt to the natural environment:The working temperature of electric vehicles varies greatly. The quality level of the road surface varies greatly, and it rains heavily on a hot day. The working temperature difference is too large, the new energy vehicle aviation plug should be characterized by excellent impact resistance.4. Mass production: Since the electric car is mass production, a car or even a dozen of the same aviation plug connector, so the new energy electric vehicle connectors to meet the needs of mass production.5. Credibility.6. Body shape requirements: try to ensure that the size is small, light weight, easy to install and adjust to reduce the overall net weight of the vehicle. 7. Comply with the relevant standards and specifications for electric vehicle sensors. Daily maintenance of new energy vehicle connectors.1. Check the shape of the aviation plug:New energy vehicles need to pay attention to the shape of the equipment process, through the appropriate way to check the shape, to ensure that the connector is free of corrosion, damage and other anomalies.2. Regular inspection of the connector:New energy vehicle connectors in-depth inspection of the connector after the problem, transmission performance, stability, reliability and so on. This can not be found in time in the ordinary inspection. Choose reliable quality, good workmanship, reputable connector products and manufacturers can reduce the daily use of the problem.

2, on the 3M electronic products network platform related to the introduction and sales of products brief: 3M electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!