Categorization:Product Information

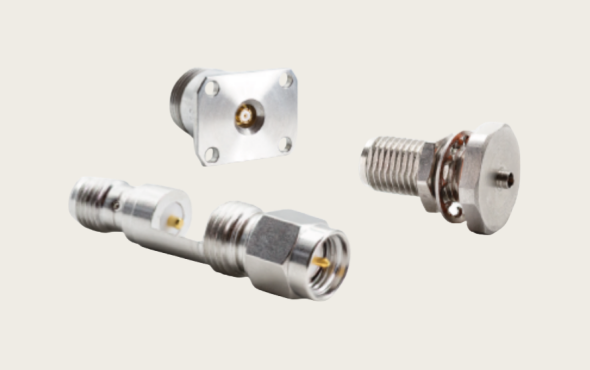

In the field of high-frequency and RF connectors, San-tron is a representative manufacturer. The brand is renowned for its high-performance RF connectors, which are widely used in industries such as defense, aviation, communication, and medical equipment. One of the outstanding advantages of San-tron products lies in their strict material control, such as maintaining a high degree of consistency in materials like stainless steel, brass, and plating processes, thereby ensuring the conductivity, corrosion resistance, and long-term reliability of the products.

San-tron uses high-grade stainless steel, low-loss alloys, and high-quality plating materials in connector production. When selecting materials, domestic manufacturers need to strictly differentiate the material characteristics required for different application scenarios, such as the use of low dielectric loss materials in high-frequency applications, and ensuring the corrosion resistance of nickel or gold plating in high salt fog environments.

The inherent performance of the material is indeed important, but the consistency of processing also determines the performance of the final product. San-tron ensures the consistency of every batch of products in the production process with strict process standards. Domestic manufacturers need to establish a comprehensive raw material testing and process traceability system to achieve replacement. From material inspection to coating thickness control, all must meet standardized requirements.

With the global emphasis on environmental protection, regulations such as RoHS and REACH have become international standards that connector manufacturers must follow. San-tron's products have already met relevant environmental protection regulations in terms of material selection. Domestic manufacturers who want to smoothly enter the international market must not only ensure stable performance but also strictly control environmental testing and material compliance.

Material control standards not only relate to product quality but also directly affect cost control. Domestic manufacturers should find a balance between performance and cost: they cannot sacrifice quality by over-compressing costs nor lose price advantages by having too high material standards. Rational supply chain management and localization of procurement will be effective means for domestic manufacturers to enhance their competitiveness.