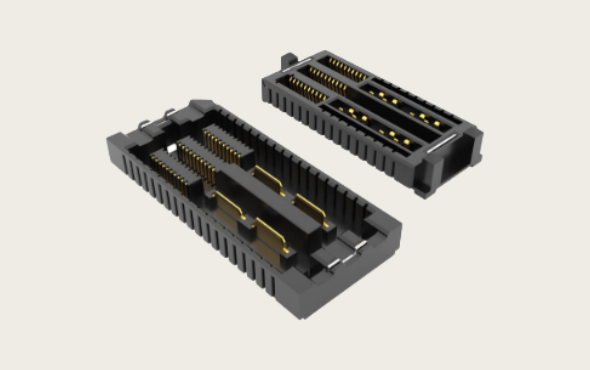

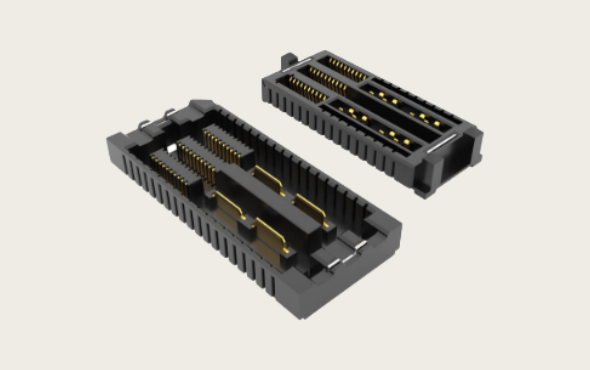

In today's world where high-speed interconnects and reliability requirements are continuously increasing, the performance and quality of connectors have become the key to the stable operation of various electronic devices. As a globally renowned high-speed connector manufacturer, Samtec's products are widely used in cutting-edge fields such as data centers, high-speed communication, automotive electronics, and industrial automation. With its precise manufacturing processes, abundant high-speed interconnect solutions, and strict quality system, Samtec has established high standards in the industry.

However, when domestic connector manufacturers try to achieve domestic substitution, quality improvement often faces the following difficulties:

Gap in precision manufacturing technology

Samtec's many products involve micro-spacing and high-speed signal integrity design, which require extremely high precision in mold making and electroplating processes. Although domestic manufacturers have made breakthroughs in some areas, on the whole, they still need to further accumulate technical and process experience.

Material and Reliability Verification

Connector key materials such as high-performance insulators and high-frequency copper alloys directly affect the lifespan of insertion and extraction and signal integrity. Some domestic enterprises still have deficiencies in material selection and long-term reliability verification.

International standards and certification barriers

Samtec's products comply with a variety of international standards (such as IEC, UL, RoHS, REACH, etc.) and have accumulated customer trust in the high-end market. Domestic manufacturers still need to invest more resources in the connection between the certification system and international quality standards.

4. Stringent requirements for customer application scenarios

Autonomous driving, 5G communication, and high-speed computing fields put extremely stringent requirements on connectors, such as ultra-low latency, strong anti-interference, and extremely high durability. Domestic manufacturers need to repeatedly test and optimize in actual applications before mass supply, in order to gradually narrow the gap.

Domestic connectors are developing rapidly under market demand and policy support, but to truly compete with international brands like Samtec in the high-end application fields, it is necessary to continuously break through in aspects such as process details, material reliability, and certification systems. Only by solving these "quality improvement difficulties" can the path of domestic substitution be more stable and long-term.

If you are interested in the domestic substitute products for this brand connector or have procurement needs, or if you have production or sales channels for the domestic substitutes of this brand connector and wish to engage in in-depth cooperation or communication, please contact via this contact information:

Manager Zhang (18665383950, same WeChat number)Contact us, we look forward to working together with more industry partners.