With the continuous advancement of industrial automation, intelligent manufacturing, and Industry 4.0, efficient and reliable connection solutions are particularly crucial for the stable operation of sensing systems. As a global leading supplier of intelligent sensors and automation solutions, SICK, Inc. not only has a deep accumulation in the field of sensors but also plays an indispensable role in the application of cable components and connection technologies in industrial fields. This article will focus on the cable component products of the SICK brand, while also combining selection suggestions and alternative directions, to provide references for engineering selection and integration.

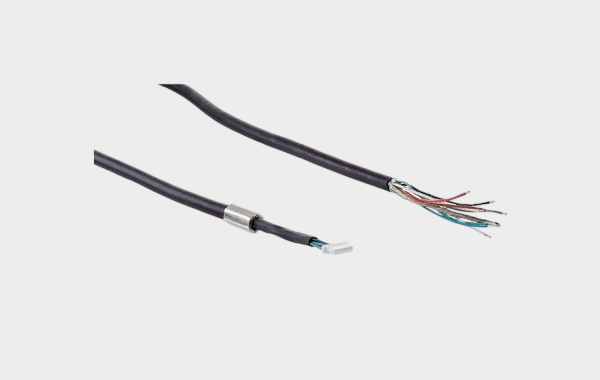

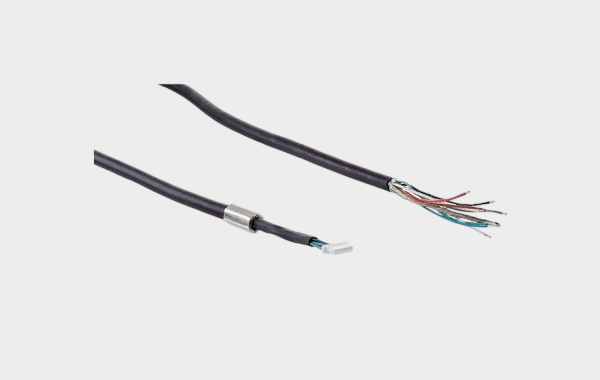

Sensor cable assembly overview: stable connection, reliable transmission

In automation control, positioning detection, and intelligent perception systems, sensor cables not only undertake signal transmission but also need to ensure power supply, communication stability, and environmental adaptability. SICK's cable assembly covers a variety of series including industrial standard interfaces such as M8/M12, sensor-actuator connection cables, and modular expansion harnesses, adapting to the needs of different working sites and industrial equipment. The product design emphasizes IP grade adaptability, anti-interference, and durability, which can support long-term stable operation under stringent industrial environments. When paired with SICK's sensor equipment, the cable assembly can achieve precise and reliable data and power transmission, reduce on-site wiring complexity, and improve the overall efficiency of the system. For example, common M12 4-pin sensor connection cables and A-coded sensor/actuator cables can meet the interface standard requirements of different field equipment.

Two, selection and compatibility reference: precise matching, domestic substitution approach

In practical engineering applications, the correct selection of cable components is crucial for system stability and maintainability. The following are some key selection suggestions and compatibility considerations:

Interface type and pin count match

Select M8, M12, or other standard interfaces according to the device sensing port; different pin numbers (such as 3-pin, 4-pin) correspond to different signal/power layouts.

Ensure that the selected cable is compatible with the sensor's interface and communication protocol; otherwise, it may cause signal loss or unstable connection.

2. Environmental Conditions and Cable Material Selection

Select appropriate materials (such as PUR, PVC) based on on-site working conditions such as temperature, humidity, and chemical corrosion.

In special environments with high requirements for oil resistance, water resistance, and other factors, prioritize products with higher protection levels and shielding layer designs.

3. Research on Domestic Compatibility and Replacement Solutions

With the continuous advancement of the localization process in the field of industrial components, the domestic alternative solutions for SICK brand cable components are gradually maturing. Domestic high-performance connection cables and industrial bus cable products have reached a certain level of competitiveness in terms of specification matching, shielding performance, and stability.

Ensure consistency of size and interface: Make sure that the domestic alternative harnesses are compatible with the original SICK cables in terms of interface size, pin count, and coding.

Electrical and mechanical performance equivalence verification: Conduct durability, interference resistance, and transmission stability tests on domestic products to ensure they meet the long-term operation requirements on-site.

• Coordinating with verification and expert evaluation: Combine the protocol specifications of on-site equipment and system requirements, and work with suppliers to complete compatibility assessment.

In the process of domestic substitution, it is advisable to conduct prototype testing and system integration evaluation in advance to ensure the effectiveness of the substitution solution.

Section 3: Application Scenarios and Advantages Value

SICK's cable components are widely used in industrial fields such as automatic production lines, robot perception modules, logistics automatic sorting systems, laser radar, and safety interlock systems. In these scenarios, high-precision sensing equipment has extremely high stability requirements for the connecting cables. SICK cable components provide stable and accurate data and power support for sensing systems through strict industrial standard certification and a wealth of interface solutions, reducing on-site fault risks and improving the overall reliability of the system.

The SICK sensor cable assembly is an important connection component in industrial perception systems, performing excellently in terms of reliability, compatibility, and industrial-grade performance. Whether in traditional automation equipment or in emerging intelligent manufacturing scenarios, the rational selection and high-quality cable assembly can provide a solid foundation for the stable operation of the system. Combined with the evaluation and application of domestic substitution solutions, it is also possible to reduce costs while ensuring performance and compatibility.

If you are looking for domestic alternatives and compatibility solutions for SICK brand cable components, or hope to obtain more comprehensive selection and supply support, welcome to contact: Manager Zhang

18665383950, WeChat number same). We continue to focus on the development and market application of domestic substitution products, looking forward to in-depth communication and cooperation with you.