Categorization:Harness Component

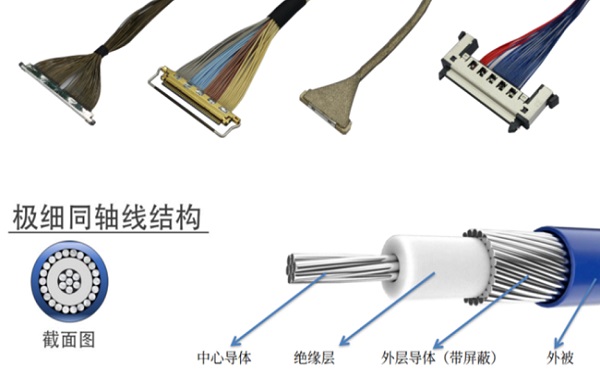

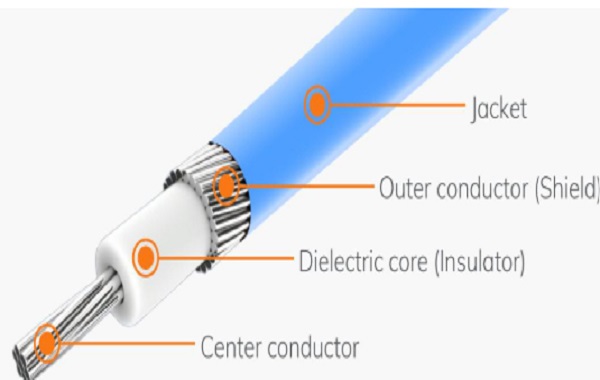

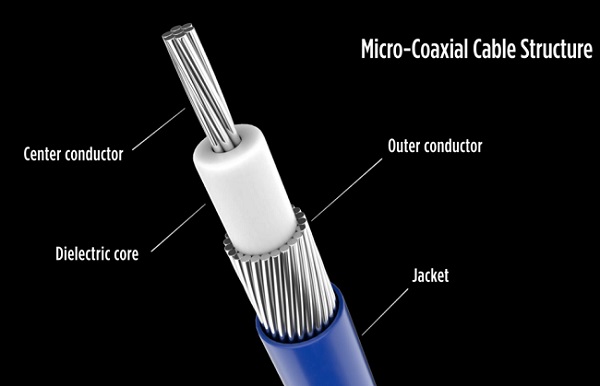

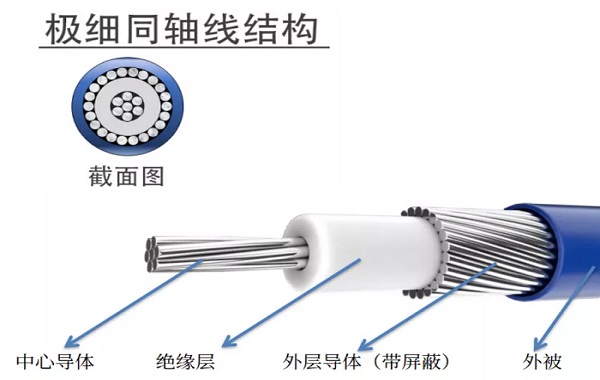

Under the background of continuous evolution in high-speed signals, radio frequency communication, and high-density electronic devices, extremely thin coaxial cable束 (Micro Coaxial Cable) has become an important transmission medium in fields such as camera modules, aerospace, industrial testing, and display systems. As the key medium between the inner conductor and the shielding layer, the insulation layer not only relates to signal integrity and attenuation but also affects lifespan, temperature reliability, and overall stability. There are significant differences in dielectric properties, loss levels, and temperature resistance among different materials, so correct selection is crucial for the quality of the cable束.

Starting from the three commonly used insulation materials, PTFE, PE, and PI, this will further analyze their applicable environments and differences in characteristics.

PTFE: The Preferred Material for High-Speed Signals and High Reliability

PTFE is renowned for its low dielectric constant and extremely low loss, making it the most advantageous insulating material for high-speed, high-frequency applications. It maintains excellent electrical stability under a wide range of temperature variations, while also boasting excellent chemical inertness and moisture resistance, making it particularly suitable for radio frequency front-end, high-speed image transmission, and devices with stringent requirements for signal integrity. However, PTFE also has a phase knee problem, which can cause a sudden change in dielectric constant when the temperature changes; in addition, its high processing difficulty leads to a significantly higher cost compared to other materials. Overall, if the core requirements of the product are high-speed, low loss, and signal stability, PTFE is the best choice for extremely fine coaxial cable bundles.

PE: Cost-effective solution, suitable for conventional and low to medium frequency applications

The outstanding advantages of PE are its low material cost and excellent processability, making it suitable for large-scale production and cost-sensitive product solutions. In extremely fine coaxial bundles, it can serve as a common insulating layer and also reduce the dielectric constant through foaming processes, further reducing signal attenuation. However, compared to PTFE, PE has higher dielectric loss and performs generally in the high-frequency field; its temperature resistance is also relatively limited, not suitable for long-term use in high-temperature environments. Therefore, PE is more suitable for electronic devices with low signal performance requirements and mild working environments, such as high-speed cables for general consumer electronics.

Three, PI: The best choice for high-temperature resistance and strict mechanical reliability requirements.

PI has unique advantages in high-temperature performance and mechanical strength, capable of withstanding working temperatures above 200°C for a long period, and it also has good fatigue resistance and dimensional stability, making it very suitable for application in extreme environments such as aerospace, engine compartments, and industrial detection. The insulation properties of PI can still maintain stability under high temperatures, but due to its higher dielectric constant compared to PTFE, it has relatively higher losses in high-frequency applications; at the same time, it requires higher process requirements in extremely fine cable structures. Therefore, PI is more suitable for professional fields that focus on temperature resistance, mechanical strength, and reliability, rather than applications that prioritize ultra-high frequency as the core indicator.

I am[Suzhou Huichengyuan Electronic Technology], long-term focused on the design and customization of high-speed signal cable harnesses and ultra-thin coaxial cable harnesses, committed to providing customers with stable and reliable high-speed interconnect solutions. If you have related needs or want to learn more, welcome to contact Manager Zhang :18913228573(WeChat number)。