Categorization:Harness Component

Many people have such doubts for the first time when they get a micro coax (miniature coaxial cable): "This wire is so thin, won't it break if I pull it?" In fact, this concern is completely unnecessary. Although the micro coaxial cable looks slender, its internal structure is as solid as that of a traditional coaxial cable. It is precisely because it has excellent mechanical and electrical properties that it is widely used in high-reliability fields such as medical probes, camera modules, drones, and industrial inspection equipment.

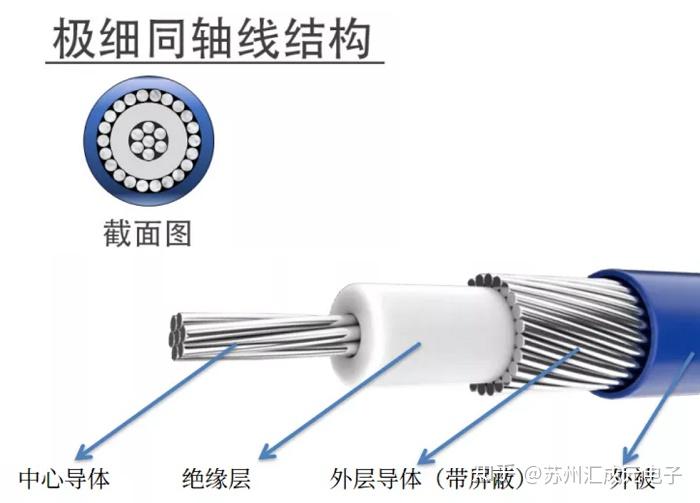

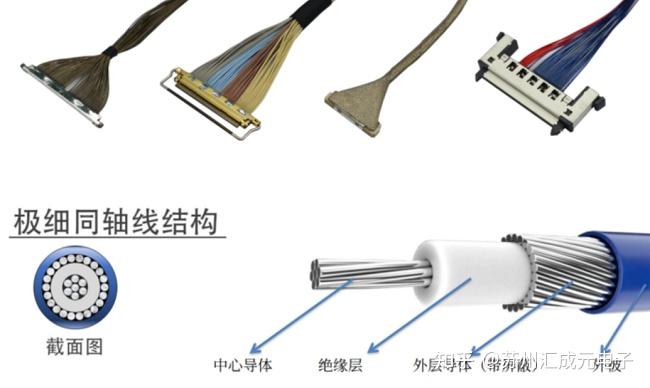

The structure is precise, with strength derived from the overall design.

The structure of extremely thin coaxial cables is clearly layered, including the conductor, insulation layer, shielding layer, and outer sheath, each layer having its unique function. The conductor is usually made of copper or copper alloys, and sometimes it is subjected to special reinforcement treatment to enhance its tensile strength. The insulation layer is often made of high polymer materials such as PTFE or FEP, which can maintain excellent electrical properties while also having good flexibility. The shielding layer is woven from fine copper wires, which can effectively prevent electromagnetic interference and also share mechanical tension. The outer sheath may sometimes incorporate wear-resistant materials to maintain stability during frequent bending applications. Therefore, the reliability of extremely thin coaxial cables is not dependent on a single material, but rather achieved through the collaborative action of multi-layer structures.

Excellent mechanical properties

Although ultra-fine coaxial cables are thinner than traditional cables, their mechanical properties are by no means fragile. Firstly, the tensile strength, within a reasonable design range, can fully withstand the tension required for daily operations, and many models can reach several newtons of tensile force in terminal separation tests. Secondly, the bending life, the minimum recommended bending radius is generally 6 times the wire diameter, but products with improved design can withstand thousands of repeated tests even at a bending radius of 1 millimeter. Moreover, the torsional life test, with common standards being ±180° or ±360° of repeated rotation cycles, can still maintain stable electrical properties under long-term stress. It is for this reason that ultra-fine coaxial cables can be widely used in high-precision and high-frequency equipment.

Part Three: Common Questions and Solutions

In practical applications, micro coaxial cables also encounter some mechanical failure issues. For example, conductor断裂 is often caused by stress concentration, which can be improved by increasing stress relief structures. Breakage of the shielding layer often occurs at locations with frequent bending, and higher density braiding or thicker outer sheath can be used. Insulation delamination problems are usually related to insufficient material adhesion, which can be effectively avoided by optimizing raw materials and processing technology. These issues may seem complex, but they can all be solved through preventive measures in the design and manufacturing stages.

Four, reliability originates from system design

Extremely fine coaxial cables, although with small size and complex structure, have completely sufficient mechanical strength, flexibility, and durability to meet the high-standard requirements of medical, communication, and imaging fields. Designers need to consider the stress conditions of tensile, bending, and torsion from the early stage of the project, rather than simply focusing on electrical performance. Only when structural design, material selection, and process control are coordinated and unified, can micro coax truly demonstrate its characteristic of "thin yet strong" and become a key connection solution for high-end electronic equipment.

The ultra-thin coaxial cable is not a fragile and easily broken cable, but a high-performance and high-reliability precision interconnection component. Its strength comes from the synergistic effect of multi-layer materials and rigorous manufacturing processes. As long as it is used and designed correctly, the micro coax can perform excellently in terms of reliability and durability.

I am[Suzhou Huichengyuan Electronics],Long-term focus on the design and customization of high-speed signal cables and ultra-thin coaxial cables, committed to providing stable and reliable high-speed interconnect solutions. If you have any related needs or would like to learn more, please contact:Manager Zhang 18913228573 (WeChat same number)。