Categorization:Harness Component

In the fields of high-speed transmission, medical equipment, industrial cameras, and intelligent terminals, extremely fine coaxial cables (Micro Coaxial Cable) play an irreplaceable role. They have a small size, excellent shielding performance, and can achieve stable high-speed signal transmission within a limited space. However, in actual use, the problem of insufficient flexibility of the cable bundle often troubles designers — it is prone to damage or failure after repeated bending. How can we improve the flexibility of the extremely fine coaxial cable bundle? Below, we will analyze from several aspects: materials, structure, process, and testing.

One, material selection determines flexibility

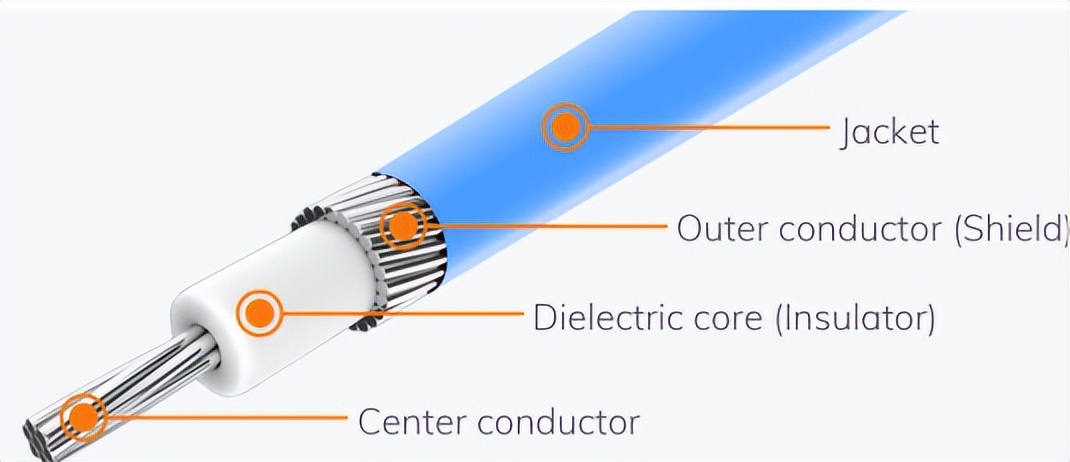

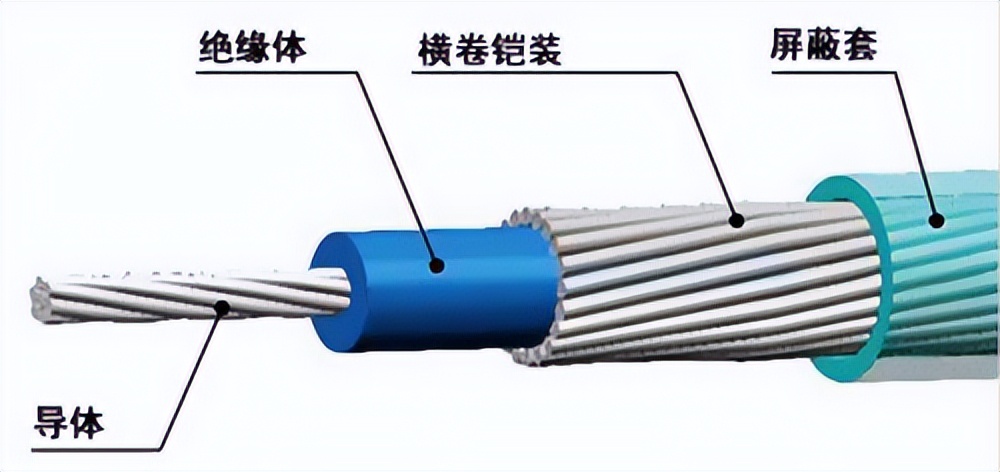

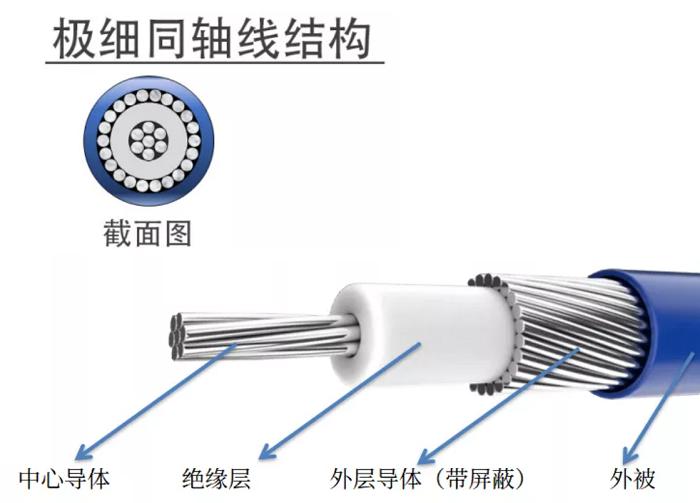

The fundamental source of flexibility comes from material selection. The conductive part generally uses ultra-fine silver-plated or tin-plated copper wire, which combines good conductivity and bendability. The outer insulating material commonly uses polytetrafluoroethylene (PTFE), polyimide (PI), or fluorinated ethylene propylene (FEP). These high-performance materials are not only soft and durable but also maintain stable dielectric properties under high temperature and high-frequency bending conditions. The combination of high-quality materials lays a solid foundation for the long-term reliable operation of the wire harness.

Two, structural optimization is the key

The flexibility of extremely thin coaxial cables is closely related to the structural design. The use of multi-strand fine wire braided conductors can effectively improve the bend life; however, if the weave density of the shielding layer is too high, it will reduce the flexibility, so a balance needs to be achieved between interference resistance and flexibility. At the same time, by reasonably controlling the outer diameter, not only can the characteristic impedance be guaranteed, but the overall bendability of the cable bundle can also be further enhanced.

Three, choose the "four-layer structure" for its flexibility.

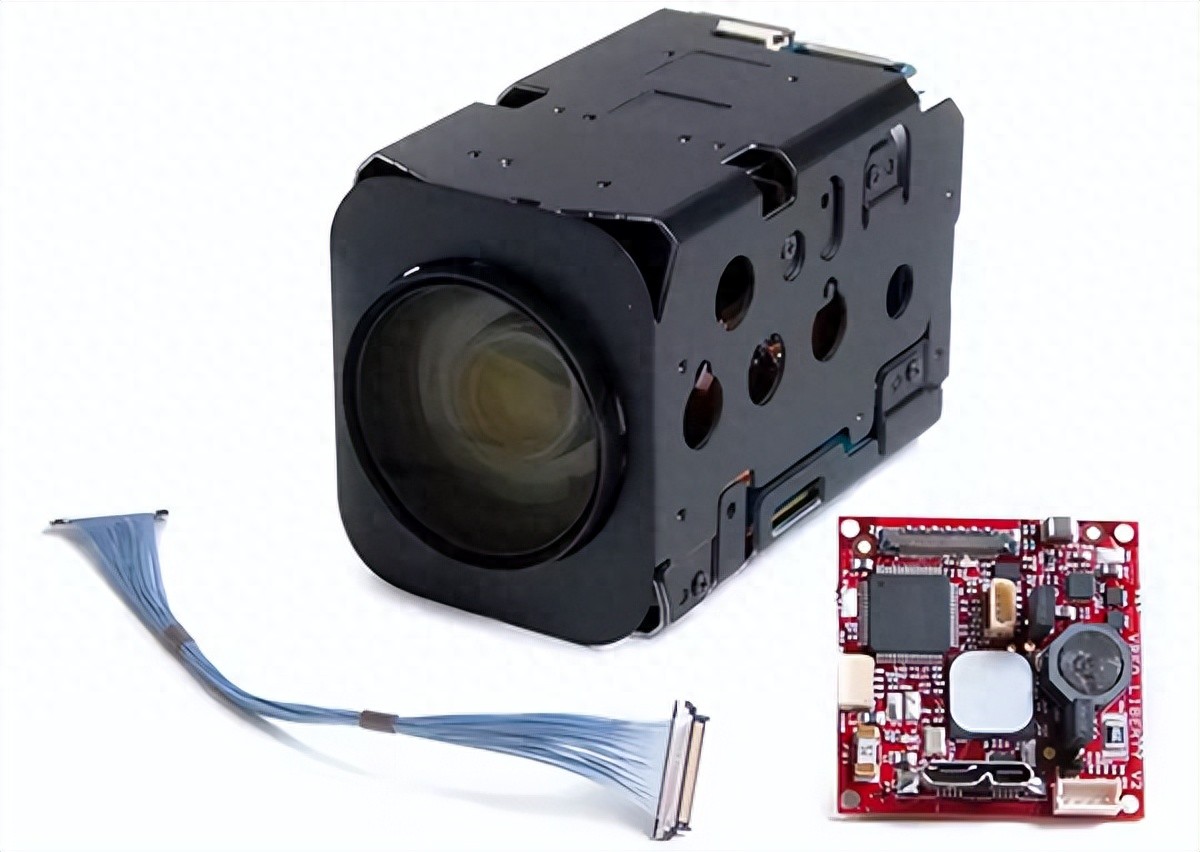

Compared with the traditional five-layer coaxial structure, the four-layer structure (conductor-insulating layer-screening layer-outer sheath) achieves a better balance between flexibility and stability. This design significantly improves the flexibility of the cable by optimizing material thickness and weaving technology while maintaining high shielding performance. Especially in narrow spaces or high-frequency bending scenarios, such as camera modules, medical probes, etc., the four-layer micro coaxial cable performs even better.

Four, the processing technology is also very important.

The flexibility not only depends on the material itself, but the processing process also has an important impact on its performance. Rational wire harness forming methods, flexible sheath design, and the selection of packaging auxiliary materials can effectively reduce concentrated bending stress and prevent local fatigue damage. At the same time, the temperature control and crimping accuracy in the process are also directly related to the stability of the wire harness during long-term use.

Five, verify the reliability of verification and testing assurance

Different application scenarios have varying requirements for flexibility. Medical endoscope equipment requires cables to withstand tens of thousands of extreme bends without damage, while industrial robots are more concerned about vibration resistance and wear resistance. By means of simulation tests such as bend life, temperature resistance, and vibration resistance, design weaknesses can be identified in advance, leading to the optimization of materials and structures, making the cables more reliable and durable in actual use.

In order to enhance the flexibility of ultra-fine coaxial cables, it is necessary to comprehensively consider material selection, structural design, process control, and verification testing from multiple aspects. Only by achieving a balance between flexibility and reliability can micro coaxial cables maximize their value in high-speed and high-precision applications.

We are[Suzhou Huichengyuan Electronic]Long-term focus on the design and customization of high-speed signal cable harnesses and ultra-fine coaxial cable harnesses, committed to providing customers with high-performance and high-reliability interconnection solutions. If you have related needs or wish to learn more, please contact:Manager Zhang 18913228573 (WeChat same number)。