Categorization:Harness Component

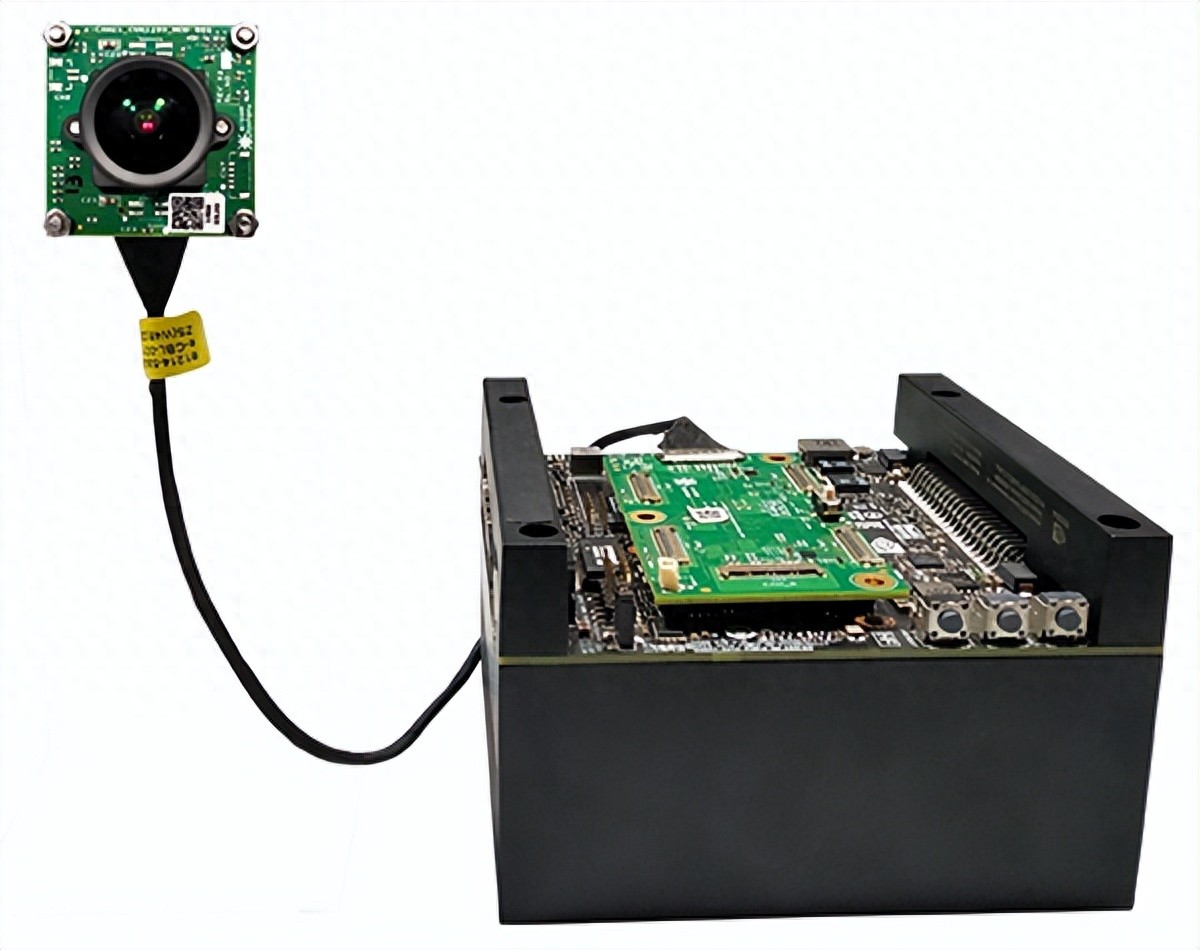

In the trend of high-speed signal transmission and equipment miniaturization, micro coaxial cable is widely used in medical equipment, drones, industrial modules, and consumer electronics. It can achieve high-bandwidth transmission within a limited space while maintaining good signal integrity. However, when the cable is terminated with a PCB board, design and process details often determine the final performance.

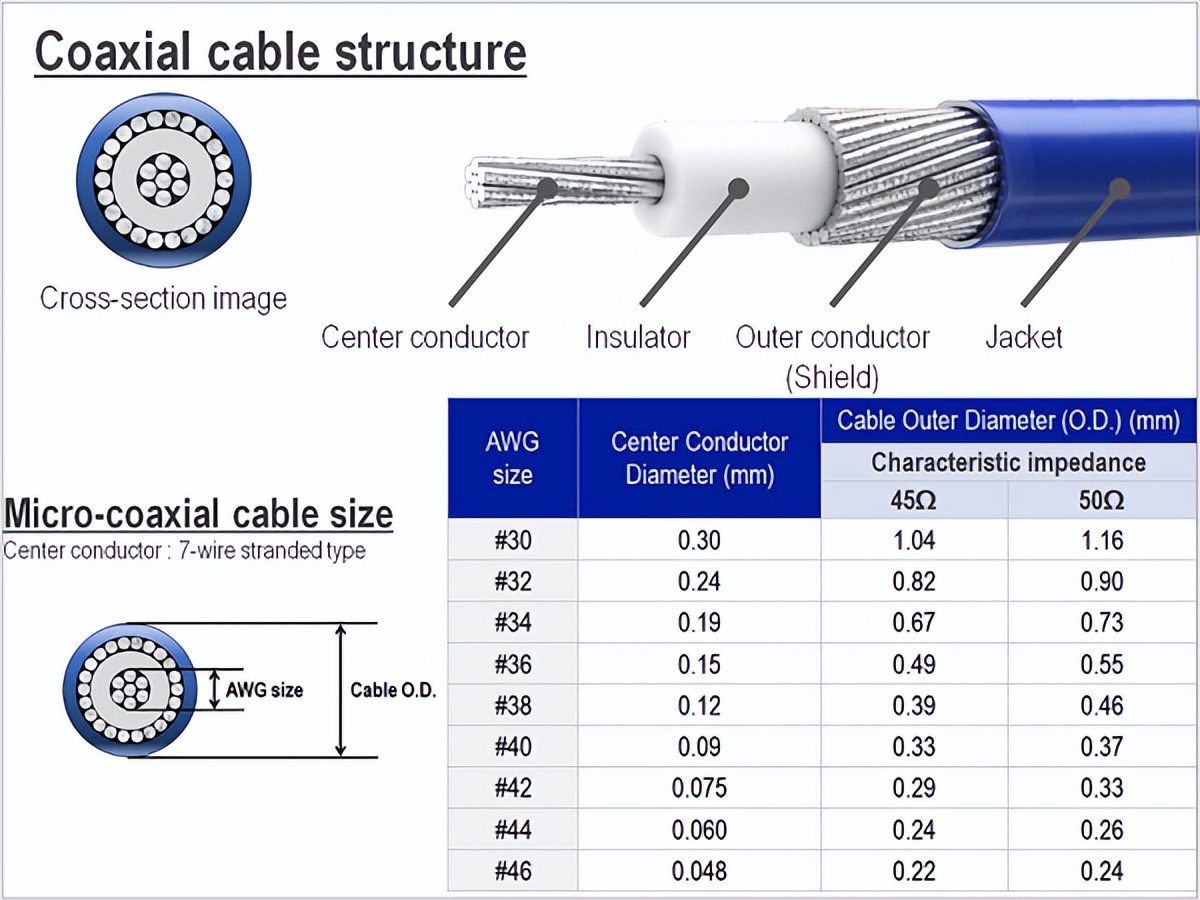

Impedance Matching and Signal Integrity

Very thin coaxial cables usually have a strict characteristic impedance (commonly 50Ω or 100Ω). If the PCB termination design is not reasonable, it is easy to cause signal reflection, crosstalk, and attenuation. To maintain signal integrity, the design should optimize trace width, ground layer structure, and via layout to ensure impedance continuity and matching.

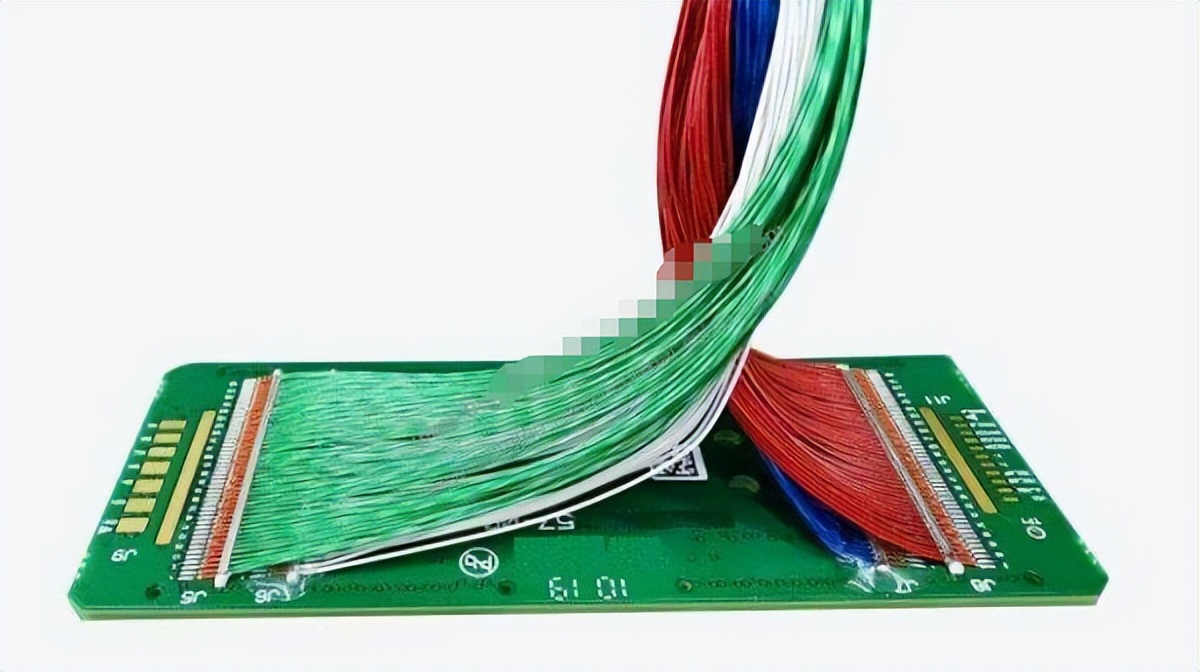

Two, the reliability of termination technology

The conductor of micro coaxial cable is extremely thin, and the general termination method is welding or a special connector. The pad size must match the wire diameter precisely, otherwise, there may be false welding or short circuits. If the temperature or time control is not properly controlled during the welding process, it may also damage the insulation layer of the wire, so the process parameters need to be strictly controlled to ensure that the solder joints are firm and reliable.

Three, mechanical stress and fixing method

The extremely thin coaxial cable is soft but fragile. If the PCB end is not designed with a reasonable stress relief structure, it may break or have poor contact during long-term use. A common optimization solution is to reinforce the terminal area with adhesive or fix it through structural components to reduce the direct force acting on the cable.

Four, consideration of Electromagnetic Compatibility (EMC)

The terminal position is often the opening point of the shielding layer, and improper handling can easily cause electromagnetic leakage or interference. Optimizing the grounding method and maintaining the continuity of the shielding layer is an important link to ensure the stability of the system's EMC performance.

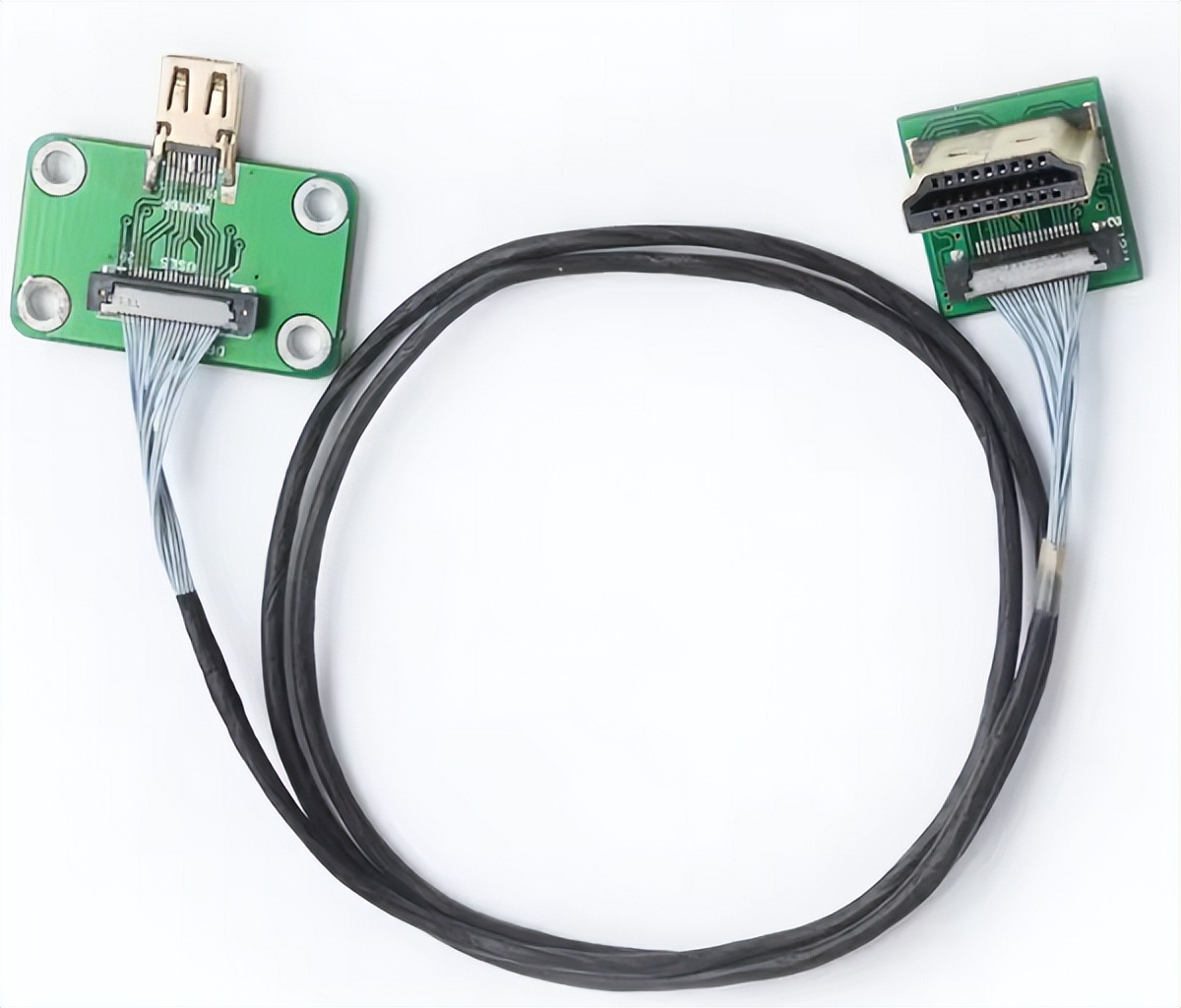

The design of the termination for ultra-fine coaxial cable束 may be subtle, but it concerns the stability of performance and service life of the entire product. Only by ensuring electrical matching, process quality, mechanical protection, and electromagnetic compatibility can the advantages of ultra-fine coaxial cable束 in high-performance equipment truly be brought into play.

I am[Suzhou Hui Cheng Yuan Electronic], focusing on the design and customization of high-speed signal cables and ultra-fine coaxial cables, committed to providing high-reliability and high-performance interconnection solutions. If you have customization needs or technical consultation, please contact:Manager Zhang 18913228573 (same as WeChat)。