Categorization:Product Information

I. How to deal with common connector terminal problems?1, poor contact: the metal conductor inside the precision connector terminal is the core part of the terminal voltage, it will come from the outside of the wire or cable, the contact current or signal is sent to the said connector to match with the corresponding upper part. So the contact piece must have excellent structure, stable and reliable contact force and good electrical conductivity. Due to the structure of the contact design is not reasonable, the selection of the wrong material, mold and not stable, processing dimensional tolerances, surface roughness, heat treatment, plating and other surface treatment process is unreasonable, improper assembly, storage and use of poor environmental and improper use of the operation will be in the contact of the bit and the contact caused by poor contact with the contact part of the matching parts of the contact part. 2, poor insulation: Insulators are in contact with the contact to maintain the correct position arrangement, and with the contact contact with the contact part of the contact. The position of the arrangement, and with the role of the contact contact between the component and the shell of the role of the contact with each other insulated. Insulating components must have excellent electrical, mechanical and molding properties of the process. Especially with the high-density, commonly used miniaturized terminals, more and more insulators with thin effective wall thicknesses. This places stricter demands on the insulating material, the injection mold and the precision molding technology. Due to metal extra, the insulator's surface or inner surface of the dust flux contamination moisture, organic materials precipitates and harmful gases adsorption film and the presence of surface water film is formed by ionic conduction channels, moisture, mildew, material aging of the absorption of the fusion of insulating properties, will cause short circuit, leakage current, breakdown, insulation resistance of the phenomenon of low insulation bad. 3, poor fixation: not only insulated insulators, usually for the contact Extension to provide centering and protection, but also has a function of mounting and positioning, locking and fixing in the device. Fixed poorly, the light affects the reliable contact caused by transient power, serious disintegration of the product. Disintegration is caused by material, design, technical and other reasons between the plug and socket structure to be together at the plug terminals, is reliable which, between the pins and jacks is not normal separation will lead to serious consequences, power transmission and signal control interruption control. Because the design is unreliable, improper selection of major errors, forming process, heat treatment, molds, assembly, welding process of poor quality, assembly is not in place will cause bad fixing.

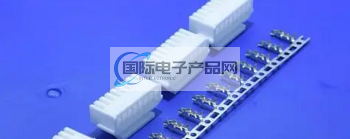

-Second, on the international electronic products network platform related to the introduction and sales of products brief: international electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the Division I business personnel below; If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!