Categorization:Product Information

I. Aluminum alloy cable and copper core cable performance ratio is how? 1. conductive ability with the same specifications of the cable for comparison, the conductivity of aluminum alloy conductor is the most commonly used benchmark material copper 61%, the specific gravity of aluminum alloy 2.7g/cm³, the specific gravity of copper 8.9g/cm³, in the same volume, the weight of the aluminum is about one-third of the weight of the copper, according to the calculations, in order to meet the same electrical conductivity premise, aluminum alloy power cable weight is half of the same capacity copper cable. 2. The weight of aluminum alloy power cable is half of that of copper cable with the same current-carrying capacity.2. Creep resistance Aluminum alloy conductor special alloy formula and heat treatment process greatly reduces the tendency of "creep" of metal under heat and pressure, and copper conductor creep performance is basically the same as that of the copper conductor, and copper conductor manufacturing connection is as stable.3. Corrosion resistance Compared to copper-core cable, aluminum alloy power cable is more corrosion-resistant than copper-core cable. Compared with copper-core cables, aluminum alloy power cables have higher corrosion resistance, able to withstand various forms of corrosion; with better oxidation resistance, oxidation corrosion resistance for copper-core cables 10 to 100 times. In sulfur-containing environments, such as railroad tunnels and other similar places, the corrosion resistance of aluminum alloy power cables is much better than that of copper-core cables.4. Mechanical Properties (1) bending performance. According to GB/T12706 in the installation of copper cable bending radius, copper cable bending radius is 10-20 times the diameter of the cable, aluminum alloy power cable bending radius of the minimum of 7 times the diameter of the cable, the use of aluminum alloy power cables to reduce the installation layout of the space, reducing the cost of installation, easier to lay. (2) Flexibility. Aluminum alloy power cables have stronger flexibility than copper core cables, even if repeated force, will not produce cracks. Reduces the safety hazards arising from the installation process. (3) Tensile strength and elongation. The tensile strength of aluminum alloy power cable is 1.3 times that of copper core cable, and the elongation rate can reach or exceed 30%, which enhances the reliability and aesthetics of long span installation.

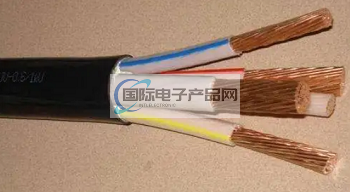

-Second, on the international electronic products network platform related to the introduction and sales of products brief: international electronic products network - a professional agent / production / sales of all kinds of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!