Categorization:Product Information

I. What are the key points of connector pin pinning?The parameters and material standards of pin pinning are mainly reflected in its contact resistance.The additional resistance in the contact area of two metal conductors is called the contact resistance.The contact resistance of two metal conductors is called the contact resistance.The contact resistance of two metal conductors is called the contact resistance. Under the microscope, contact occurs only at certain contact points. The current conductor shrinks on the contact surface, creating a shrinkage resistance Rs. In addition, a thin film (e.g. an oxide film) quickly forms on the contact surface when exposed to air, as well as a thin layer of resistance Rb. Then there is its pin pressure F, which actually acts on the two pins to bring them into contact. Increasing the pin pressure decreases Rj because the increased pressure makes the contact area larger. Additionally, the increased pressure also breaks down the film, which decreases Rb. Temperature changes are also important to know before using the device. pin pins have a tendency to have higher pin temperatures after a long period of time when they are powered up. This change is not only related to the current, material and size of the pin, but also to the pressure on the pin. pin pins also have certain requirements on the material. Physical properties such as specific resistance, mechanical strength, and chemical properties will directly affect the contact resistance. When selecting materials, a combination of reduced shrinkage resistance Rs and thin-layer resistance Rb needs to be considered. Technically, pin pins can be operated at normal currents without causing the pin temperature to rise too high. Short circuit current tolerance. Moderate insertion and extraction work. Overall, it's actually quite easy to work with. Of course, it should be noted here that in the actual design process, the contact resistance is very difficult to calculate and requires a lot of experiments and good experience. In short, it is a high-precision products, tolerance requirements for ± 0.001-± 0.0005. ceramic powder injection molding production of ceramic rings, the core pin requires acid resistance, corrosion resistance, high temperature resistance and a series of high requirements of the environment, especially carbide and other industrial teeth. High temperature corrosive environment operation. In the process of ceramic powder injection molding mold production of nano zirconia, cemented carbide core pins are suitable for its high temperature working environment, and its long term durable operation makes the scale and batch production of ceramic ferrule become a trend. Direct expression. pin pin production is also mainly based on different models of core pins for different equipment and operations. Ceramic ferrule core pin and PIN pin can be customized according to the requirements of the core pin can be customized according to the matching requirements of ceramic powder injection molding mold processing. Due to the high precision requirements of ceramic core pins, they are generally customized according to the drawing requirements.

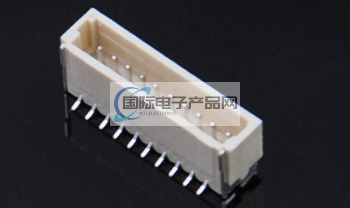

-Second, on the international electronic products network platform related to the introduction and sales of products brief: international electronic products network - a professional agent / production / sales of all kinds of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!