Categorization:Product Information

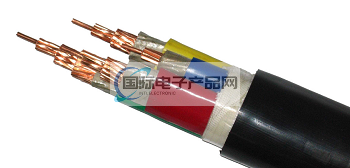

ONE. What are the structural components of the robot cable? Conductor structure industrial robot cable should choose more flexible conductor, in general the thinner the conductor, the better the flexibility of the cable, but the conductor is too thin, will produce cable winding phenomenon. A number of long-term experiments provide a better diameter of a single conductor, it has a better tensile capacity and the most flexible performance. The insulating materials in core insulated cables must not stick to each other, and the insulation also needs to support each single strand of wire. Therefore, only high-pressure molded insulation for industrial robotic cables can prove its reliability over the course of millions of meters of cable application. Tensile elements in the center of industrial robotic cables depending on the number of cores and the number of spaces in the intersection area of each core as much as possible with a real center wire filling (not, as is often the case, with some filler material or waste plastic made of junk core filling) This method effectively protects the stranded structure and prevents the stranded wires from wandering away from the center area of the cable. The strand structure must be wound around a stable tensile center at a better intersecting pitch. At the same time, due to the use of insulating materials, the stranded structure should be designed for motion and industrial robot cables should be glued in bundles starting with 12 cores. Instead of cheap woolen materials, fillers or accessory fillers, the inner jacket is extruded in a gastric style. This method ensures that the stranded wire structure does not come apart. The shielding tissue layer is tightly braided outside the inner jacket with optimized braiding angles. Loose braid reduces EMC protection and the shielding quickly fails due to shield breakage. The tightly woven shielding is torsionally resistant to coworkers. The outer jacket is made of different modified materials with different functions, ranging from UV-resistant to low-temperature-resistant, oil-resistant and cost-optimized. But all of them have one thing in common, high abrasion resistance and do not adhere to anything. The sheaths of industrial robot cables must be highly flexible but also supportive, and should of course be high-pressure molded.

-Second, on the international electronic products network platform related to the introduction and sales of products brief: international electronic products network - a professional agent / production / sales of all kinds of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!