Categorization:Product Information

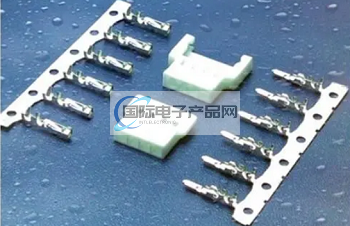

I. What raw materials are used to make the connector PIN pins?Most of the PIN pins are made by choosing tungsten carbide as the raw material. Because the pin pins are used to complete the electrical (signal) conduction of the connector. Therefore, the material requirement of the pin must be able to transmit electrical (signal). In addition, since heat tends to be generated during electrical (signal) conduction, the corresponding pins must be sufficiently heat resistant. On the other hand, the PIN pins also serve a connecting function and thus need to be pulled out and inserted frequently, thus requiring that the material of the PIN pins must be sufficiently hard and wear-resistant. In addition, the PIN pin also acts as a conductor and connecting electrical (signal), and therefore must be sufficiently resistant to corrosion so as not to affect the use of the connector.The processing of PIN pins is roughly divided into the following processes: 1. Turning: Selection of copper rods to be added to the supply pipeline of the fasteners and fixed. The parts from the car should be compared with the paper to measure the size, to confirm that the parts made are in accordance with the size and tolerance requirements, and through the microscope to observe the appearance of the requirements. 2, the pin tube rectification: in the rectification frame poured into the appropriate amount of pins, set the mechanical parameters, and then put the rectification frame into the rectification frame, press the green start button to fix the rectification frame. The machine vibrates to make the needle into the hole.3. Spring whole column: pour the appropriate amount of spring into the whole spring column, grab the spring plate and the whole hot box, rock back and forth to make the spring fall into the hole.4. Needle whole column: pour the appropriate amount of needle into the whole column, and then, grab the whole frame of the whole column rock back and forth to make the needle fall into the hole.5. Riveting: check whether there is insufficient spring or insufficient needles in the shaft, the needle is crooked products corrected with tweezers , after confirming that there is no error, according to the direction of the completion plate gently placed on the riveting platform, rivets automatically add rivets.6. Compression of the whole inspection: for each needle with a press head compression 3 ~ 5 times, to check whether there is a crooked needle, shrinkage of needles, folding needles, pressure injuries, plating color, coating off and other undesirable phenomena.7. Rubber core, single needle whole column, rotating plate: in the whole column poured into the appropriate amount of single needles, grab the single needles and the whole column of the frame, shaken back and forth, so that the single needles fall into the hole.

-Second, on the international electronic products network platform related to the introduction and sales of products brief: international electronic products network - a professional agent / production / sales of all kinds of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!