Categorization:Product Information

I. What is the reason for the insulation degradation of silicone rubber insulated cables? Silicone rubber cable is characterized by high temperature resistance, corrosion resistance, etc., many electrical equipment will be used in the silicone rubber insulated cable, and is widely used in various industrial fields. But most of the reasons for the failure of silicone rubber cable is the cable insulation is reduced resulting in breakdown, so what are the reasons for the reduction of cable insulation?1. External damage by the operation of the analysis in recent years, especially in today's rapid economic development, and now a considerable number of cable failures are due to mechanical damage caused by the 2. Insulation dampness This is also a very common situation, which generally occurs in the direct burial or rows of pipes in the Cable joints. For example: cable joints production is not qualified and in humid climatic conditions to do joints, will make the joints into the water or mixed with water vapor, time in the electric field under the action of the formation of water twigs, and gradually damage the cable's insulating strength and cause failures. 3. chemical corrosion of silicone rubber high-temperature cables are buried directly in the role of acids and alkalis in the region, often resulting in the corrosion of high-temperature silicone rubber cables of the outer protective layer, the protective layer because of the long-term exposure to chemical corrosion Or electrolytic corrosion, resulting in the failure of the protective layer, insulation reduction, will also lead to silicone rubber high temperature cable failure. 4. long-term overload operation overload operation, due to the thermal effect of the current, the load current through the cable will inevitably lead to the conductor heat, while the skin effect of the charge and the steel armor of eddy current loss, insulation medium loss will also be produced at first additional heat, so that the temperature of the cable. Long-term overload operation, the high temperature will accelerate the aging of the insulation, so that the insulation is broken. Especially in the hot summer, the temperature rise of the cable often leads to the first cable insulation weakness is broken, so in the summer, the cable failure is particularly more. 5. cable joints failure cable joints is a cable line in the assortment of weak links, by the personnel directly negligence (poor construction) triggered by the failure of the cable joints often occurs. Construction personnel in the production of cable joints in the process, if there is a joint crimping is not tight, heating is not sufficient and other original network, will lead to the cable head insulation is reduced, thus causing accidents.6. Environment and temperature of the cable is located in the external environment and the heat source can also cause the cable temperature is too high, the insulation breakdown, and even the explosion of the fire.7. Other factors of the cable body's normal aging or natural disasters and other reasons.

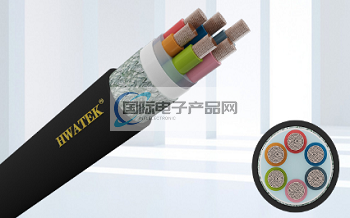

-Second, on the international electronic products network platform related to the introduction and sales of products brief: international electronic products network - a professional agent / production / sales of all kinds of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!