Categorization:Product Information

I. Methods of testing cable resistance can be categorized into which ones?1. Insulation resistance test. Insulation resistance measurements of wire and cable must be converted to insulation resistance values per kilometer. Unlike DC resistance, the value of insulation resistance is inversely proportional to the length of the wire and cable. There are four insulation resistance measurement voltages for low-voltage wire and cable: 100V, 250V, 500V and 1000V, of which 100V and 500V for quality. Inspection departments are widely used in the inspection, the length of the measured wire and cable is not specified, but generally used 10 meters measurement, easy to measure and calculate. Charging time before measurement is usually 1 minute. Wire and cable insulation resistance testing is generally used voltage-current method, also known as high resistance meter method. Some wires and cables have metal protective sheaths and shielding. For this type of wire and cable insulation resistance measurement, the main measurement of insulation resistance between the conductor and the metal sheath or shield or armor layer; for wire and cable without metal sheath, the measured insulation resistance value of the wire and cable must be E first immersed in water. Measure the insulation resistance between the conductor and water, the sample must be adapted to the water temperature. 2. DC resistance test. Relevant standards specify that the DC resistance of wire and cable should be based on the resistance of the conductor per kilometer, DC resistance measurement data of wire and cable must be 20 ℃ converted to DC resistance per kilometer. DC resistance value for 20 ℃ DC resistance value is less than the specified standard value, wire and cable samples qualified, otherwise unqualified.3. Industrial frequency voltage check. Usually use AC voltage to measure the frequency withstand voltage. The standard AC voltage and sinusoidal similar to the frequency of 49Hz ~ 61Hz rated voltage 450/750V insulation thickness of less than 0.6mm with 1500V high voltage, insulation thickness of less than 0.6mm with 2000V high voltage. Insulation thickness greater than 0.6mm, if the sample of the wire and cable under test is not pierced or damaged, the voltage is applied for 5 minutes.4, mechanical properties check. Mechanical properties mainly refers to the tensile strength of wire and cable before and after aging. According to the relevant standards, aging wire and cable samples should be made using forced ventilation aging box, the test should be as close as possible to the unaged parts. Mechanical properties are usually measured directly with an electronic tensile measuring instrument. First, use the thickness gauge to accurately measure the width and thickness of the middle part of the wire and cable under test, and then manually and promptly in the blast drying oven, and then measured by electronic tensile strength machine. Record the elongation distance and greater tensile stress of the wire and cable in the process of tensile fracture, and calculate the measured wire and cable according to the data obtained. The tensile strength and elongation at break before and after aging can be judged by comparing with the product standard.

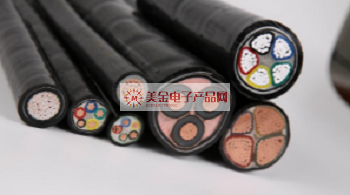

-Second, on the U.S. dollars electronic products network platform related to the introduction and sales of products brief: U.S. dollars electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand what we can provide connectors | harness | wire and cable products solutions, please contact our business staff below; If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!