Categorization:Product Information

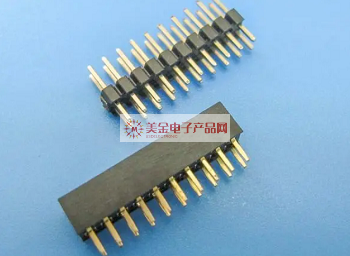

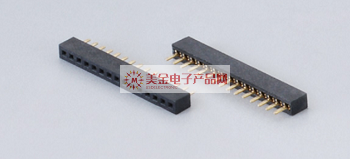

Busbar is also very versatile and is often seen in circuit boards. Quality is an essential element that affects electrical performance and workmanship. The quality problems often encountered with row mother are generally: lack of pins, unqualified flatness, insufficient holding power, the plastic does not meet the temperature resistance standard.

-I. How should the row mother connector be selected?1. Missing pins. In the production process of rows of pins and rows of mother, there are often missing pins, which need to go through the assembly process. How to ensure that the defective products do not flow into the customer is one of the key factors in the quality control of the factory. Although each product has a full inspection, it depends on the visual inspection of workers, which inevitably leads to visual fatigue. We will increase the equipment to actively detect the missing Pin on the machine to ensure that the products with missing Pin are screened out. Machine and personnel control is the main way to improve the yield rate. 2, flatness failure. Line board end welding, patch is one of the essential processes, rows of pins and rows of mother rolls with packaging, automatic patch to improve production efficiency and reduce labor costs. Then the choice of T products worried about the problem is flatness. Once a defect occurs, the product will be soldered, non-conductive, rework the process of patch welding is cumbersome, increasing costs. Therefore, in this regard, Conrad Electronics is also very careful in quality control to avoid problems. 3, the holding force did not reach the standard Holding force is a row of pins and rows of mother performance in the problem can not be ignored, but often lead to serious quality accidents. For example, the row mother of rubber core and terminal between the holding force is not enough, welding PCB is not easy to find. Once the end of welding in and row of pins inserted, the holding force is not enough will lead to row of pins will row of mother's rubber core out of the whole, leaving only row of mother terminals in the PCB board. This batch of bad, will bring serious economic losses to the enterprise. After the production of terminals or rubber cores is completed, first of all, the actual matching, holding force and insertion force is within a reasonable range, the test is qualified before warehousing. When assembling the production line, in the first piece, inspection, product sampling three links to carry out strict clamping force and plug force test, and make a detailed data record, layer by layer test fit to meet the standards before shipment. 4, plastic high temperature. Currently commonly used plastic materials are P, PA6T, PA9T and LCP, of which, P is only applicable to wave soldering, while PA6T, PA9T, LCP can be used for wave soldering and reflow soldering. SMD products are definitely reflow soldered, so be sure to understand the customer's process when requesting a quote.

-Second, on the U.S. dollars electronic products network platform related to the introduction and sales of products brief: U.S. dollars electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand what we can provide connectors | harness | wire and cable products solutions, please contact our business staff below; If you have related [connector | wire harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!