Categorization:Product Information

RJ45 connector performance on the environmental requirements of which RJ45 connector performance on the environmental requirements: common environmental performance, including temperature, humidity, salt spray, vibration and shock, etc. 1, vibration and shock vibration and shock resistance is an important performance of the electrical connector, in special applications such as aviation and aerospace, railroads and highway transportation is particularly important, it is an important indicator of the test of the connector mechanical structure, robustness and reliability of electrical contact. It is an important index to test the mechanical structure of the connector and the reliability of electrical contact. In the relevant test methods have clear provisions. Impact test should be specified in the peak acceleration, duration and impact pulse waveform, as well as the time of electrical continuity interruption. 2, temperature Currently, the connector's higher operating temperature of 200 ℃ (except for a few high-temperature special connectors), the lower temperature of -65 ℃. As the RJ45 connector work, the current generates heat at the point of contact, resulting in temperature rise, so it is generally believed that the operating temperature should be equal to the ambient temperature and the temperature rise of the contact point and the sum. In some specifications, it is specified that the connector in the rated operating current allowable higher temperature rise.3. Resistant to humidity The intrusion of moisture will affect the connection h insulation properties, and corrosion of metal parts. Constant humidity and heat test conditions for the relative humidity 90% ~ 95% (according to product specifications, up to 98%), temperature +40 ± 20 ℃, the test time according to product specifications, at least 96 hours. Alternating humidity and heat test is more severe. 4, other environmental performance according to the use of requirements, electrical connectors and other environmental performance sealing (air leakage, liquid pressure), liquid impregnation (on the ability of a particular liquid resistance to vices), low air pressure, etc. 5, salt spray Connectors in the environment containing moisture and salt work, the metal structural components, contact parts of the surface layer of the surface treatment layer may produce galvanic corrosion, affecting the connector physical and electrical properties. Connector physical and electrical properties. In order to evaluate the ability of electrical connectors to withstand this environment, the salt spray test is prescribed. It is the connector suspended in a temperature-controlled test chamber, with a specified concentration of sodium chloride solution with compressed air spray, the formation of salt spray atmosphere, the exposure time specified by the product specification, at least 48 hours.

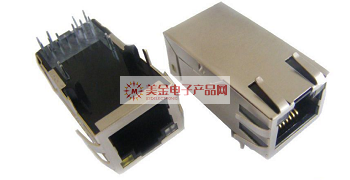

-Second, on the U.S. dollars electronic products network platform related to the introduction and sales of products brief: U.S. dollars electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!