Categorization:Product Information

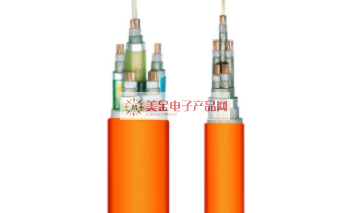

I. What are the main advantages of mineral insulated cables? Fireproof Because mineral insulated cables are all composed of inorganic materials (metallic copper and magnesium oxide powder), it will not cause fire itself, and it is not possible to burn or help combustion. Since the melting point of copper is 1083℃ and the melting point of magnesium oxide is 2800℃, this kind of cable can continue to maintain power supply in the case of a fire close to the melting point of copper, and it is a fireproof cable in the true sense of the word. At present, it can maintain power supply for three hours in a fire at 1000℃ and can withstand the impact of fire sprinkler and heavy fall of electric safety class. The thermal conductivity of magnesium oxide insulation material is much larger than that of mica insulation and organic insulation material, and the heat dissipation is good. Therefore, for the same cross-section of the cable, mineral insulated cables can be larger than the mica insulation and organic insulation cable transmission cable. As the relevant norms for fire line regulations: flame retardant, fire-resistant and other organic insulated cables must be laid openly with protective measures through the metal pipe or closed bridge, and mineral-insulated cables can be directly laid openly, and therefore can be less than the organic insulated cables to consider the reduction of coefficient of capacitance, naturally reducing the cross-section requirements for more than 16mm2 line, at least one cross-section can be reduced for the place that does not allow people to come into contact with. At least reduce two cross-section. Waterproof good mineral insulated cable using copper sheath is seamless copper tube, water molecules are completely blocked out, is a real sense of waterproof products. Explosion-proof mineral insulated cable using copper sheath is a seamless copper tube, and magnesium oxide powder is tightly compacted, flammable gases, oil vapor, flames can not reach the electrical equipment connected to the cable, so the cable has explosion-proof characteristics. Corrosion-resistant copper has good corrosion resistance, in the normal use of the environment does not require any additional protection, in special environmental conditions, such as copper has a strong corrosive effect on the environment, just add a layer of plastic outside the cable outer sheath can achieve corrosion resistance, so the cable has a very good corrosion resistance. High temperature mineral insulated cables can work continuously and normally at a high temperature of 250℃, and work for a short time at 1083℃, which is close to the melting point of copper, and the magnesium oxide insulating material will not undergo any change of nature at this time. This characteristic is suitable for use in metallurgy, cement and other high temperature environments. Resistant to mechanical damage mineral insulated cable conductor, metal sheath has a certain degree of strength and toughness, magnesium oxide in the cable processing process advantage after a high degree of compression, conductor, sheath, insulation composed of a dense whole. So the cable is subjected to impact bending, flattening, twisting and other deformation of the sheath will not be damaged, the relative position between the core wire as well as between the core wire and the sheath to remain unchanged, will not produce a short circuit, and will not affect the electrical performance. Bending radius is small, laying space is small mineral insulated cable is a dense whole, a very small bending radius is not greater than 6D (D is the diameter of the cable), so easy to install, reducing the space occupied by the line laying. Suitable for replacing bus ducts, laid in small space places. Smoke-free and non-toxic mineral insulated cables are all composed of inorganic materials (metallic copper and magnesium oxide), so instantly in the fire conditions, the cable will not spontaneously combust and will not produce smoke and toxic gases, is the real meaning of safety, cable. Overload-resistant mineral insulated cable insulation using magnesium oxide, magnesium oxide melting point is 2800 ℃, compared with ordinary plastic cables, mineral insulated cables can increase the flow capacity of a cross-section of the level, and at the same time can withstand a considerable overload, its overload capacity can reach more than 10 times the normal flow capacity. Long life mineral insulated cables are made of all inorganic materials that do not age. Service life can be calculated in accordance with the rate of oxidation and corrosion of the copper sheath. Data show that the sheath oxidation of 0.25mm at 250 ℃ ambient temperature needs 257 years, while the copper sheath thickness of mineral insulated cables are generally between 0.31-1.17mm, the actual use of the temperature is lower than 250 ℃, so the cable is a long-lasting cable.

-Second, on the U.S. dollars electronic products network platform related to the introduction and sales of products brief: U.S. dollars electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!