Categorization:Product Information

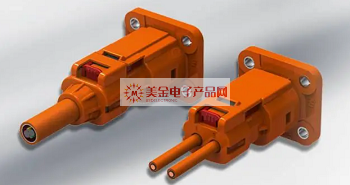

I. What is the automotive connector plug-in requirements? Automotive connector plug-in is provided by the manufacturer, including connector shell, plug-in structure and connection structure; connector shell: its upper and lower surfaces symmetrically equipped with a slide bar, connector shell upper and lower surfaces symmetrically equipped with a mounting plate on the left side of the left side of the left side of the surface of the connector shell axially equipped with three jacks; plug-in structure: symmetrically located in the front and rear surfaces of the connector shell in the right mounting groove; connection: respectively, set up in the corresponding jacks; it also includes four reinforcing bars symmetrically set at the front and rear ends of the upper and lower surfaces of the connector shell to meet the requirements of the automotive connector insertion, to make the signal more stable in transmission, to avoid the occurrence of poor contact when the vehicle vibrates, to make the operation of the workers more convenient and quick, and to reduce the workload of the workers.The U-shaped plate is symmetrically set in the mounting groove on the right side of the front and rear surfaces of the connector shell and is rotationally connected to the insertion plate through the rotating axis inside the U-shaped plate The U-shaped plate is symmetrically set in the mounting groove on the right side of the front and rear surfaces of the connector housing, and the U-shaped plate is rotationally connected to the insert plate by a rotating shaft. Four springs are symmetrically set in the mounting groove on the right side of the front and rear surfaces of the connector housing, and there is a triangular cleat uniformly distributed outside the insert plate, an anti-slip pad uniformly distributed on the right side of the triangular cleat, and an anti-slip groove uniformly distributed on the outside and right side of the insert plate to meet the automotive connector. The connection structure includes a copper column, a second spring, a slider and a top piece, the copper column is uniformly set on the front and rear inner walls of the corresponding jacks; the uniformly distributed slider is slidingly connected to the slide groove symmetrically set in the upper and lower inner walls of the three jacks; the two sliders are fixedly connected to the left and right ends of the top piece on the transverse neighboring sides; a spring II is set in the middle of the slide groove symmetrically set in the upper and lower inner walls of the three jacks; the outside end of the second spring is fixedly connected to the corresponding inner curved surface of the top piece, which can be connected to the top piece. The outer end of the second spring is fixedly connected with the corresponding inner curved surface of the top plate to avoid poor contact when the vehicle shakes. The top plate is a brass top plate, which clamps the inlet plug to a certain extent. The front and rear ends of the mounting plate are symmetrically equipped with mounting holes, which can further enhance the stability of the connector shell through the bolts.

-Second, on the U.S. dollars electronic products network platform related to the introduction and sales of products brief: U.S. dollars electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!