Categorization:Product Information

I. What are the processes of new energy vehicle electrical connectors? New energy vehicle electrical connector is a connector category, is accompanied by China's new energy vehicle development trend in recent years, slowly extracted from the traditional high-voltage large electric flow and the traditional low-voltage automotive connectors in a class of connectors, compared to the traditional high-voltage large electric flow connector, new energy vehicle electrical connector application work situation is more complex, the connector of the credibility of the provisions of a higher. Compared with the traditional low-voltage automotive electrical connectors, because of the increase in the rated voltage, enhance the risk of damage to the body from high-voltage electric shock, the new energy automotive connector safety coefficient is higher, so the insulating layer of the goods, safety and protection provisions than the traditional low-voltage software have been gradually improved. 1. detailed manufacturing and processing process: the processing process is critical for the spacing between the small thin and thick, and other technicalities, some companies have already been carried out. Interval of less than 0.4mm new energy vehicle connector manufacturing scientific research. This kind of technology can ensure that enterprises in the ultra-detailed manufacturing industry to achieve international standards in the same industry. Light source signal and electromechanical engineering structure fusion development and design: this technology can be applied to the sound frequency connector embedded in electronic device parts. According to add IC, LED and other electronic components in the audio connector, so that the audio new energy vehicle connector in addition to the role of transmitting pulse signals and data signals, and thus enhance the current stage of the audio connector to the foot-type touch method to carry out the on-off transmission of the design scheme. 2. Ultra-low-temperature and low-pressure molding production process: the use of hot-melt raw materials of the airtightness and the physics of the characteristics of the insulating layer of high-temperature resistance, etc., after sealing, the cable maintenance of the international standard. The role of the cable maintenance welding welding points after packaging will not be pulled by external forces. And DC power new energy vehicle connector itself and cable packaging with insulation layer, high temperature resistance, impact resistance, etc., to ensure that the product quality credibility, will continue to develop and design the use of different products in the future.

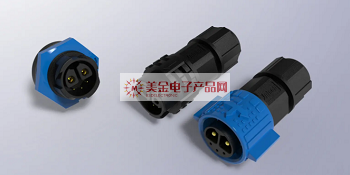

-Second, on the U.S. dollars electronic products network platform related to the introduction and sales of products brief: U.S. dollars electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!