Categorization:Product Information

I. Why connectors are better than hardwiring?1. Connectors save time and cost over hardwiring. Most industrial equipment contains a large number of wires between its components and subsystems. When an OEM manufactures a product, it is usually assembled at the factory prior to delivery, then the system is disassembled, disconnected and transported to the end user where it is reassembled. This can be a very time-consuming task if all the cables need to be hardwired to the system, then disassembled and then rewired in the field. Pre-assembled connectors ensure that cables are connected directly to the connector, making the manufacture, installation and maintenance of equipment more efficient, cost-effective and reliable. It is easier to remove connections and re-match connectors at each subsequent stage of the product's life cycle. This reduces the total time for termination and completely eliminates the need for field termination. In short, connectors allow orders to be installed faster than with typical hardwiring.2. Connectors are more flexible and easier to maintain than hardwiring. With connector-based wiring, connector-compatible components and subsystems can be disconnected and swapped with other components as needed, increasing system flexibility by eliminating the time and cost of rewiring each time equipment is moved, upgraded, or replaced. This supports the trend toward modularity in the industrial sector, allowing systems to be rearranged for different shop operations or easily disassembled and reassembled during maintenance. In fact, most connectors themselves are modular and can be configured by the user as a transmission medium to accommodate different voltages, thus reducing the total number of cables and connectors required.3. Connectors are easier to remove the risk of contamination than hard wiring. Sensitive electronic equipment designed for harsh industrial environments is often placed in waterproof and dustproof housings to protect against unfavorable manufacturing factors. However, if rewiring is required for installation and maintenance, these enclosures need to be opened to connect the cables, which can increase the immediate risk of contamination during the wiring process, but the greater risk is of damaging or incorrectly setting the enclosure seals, resulting in the potential for contaminants to enter the enclosure, build up over time, and ultimately lead to contamination that can seriously damage the equipment. The use of connectors eliminates this risk because the connector will be entering and pulling out of the enclosure, but pre-assembled connectors designed for harsh environments are sealed around the body of the connector and to some degree around the connection area itself to protect the terminals from intrusion, vibration, and harsh temperatures. If contamination occurs, it will contaminate the connector, not the electrical/electronic equipment in the enclosure.4. Connector errors are less than those of hardwiring. In addition to the obvious disadvantages in processing time, wiring errors can lead to unexpected costs during installation or maintenance. The use of connectors reduces the skill of the installer or maintenance person and does not cause damage due to wiring errors.5. Connectors cause less waste than hardwiring. Connectors reduce a range of unnecessary material waste, such as expensive cables (shortened by repetitive wiring) and other electrical consumables (e.g., crimp terminals) that add up over time.

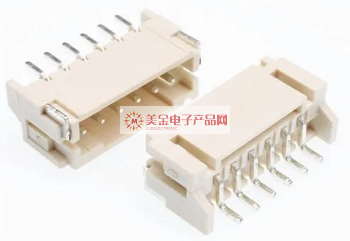

-Second, on the U.S. dollars electronic products network platform related to the introduction and sales of products brief: U.S. dollars electronic products network - professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact the following Division Division I business personnel; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" with the person to discuss!