Categorization:Product Information

NAIS|Matsushita Electric Connectors for substrate-to-substrate and substrate-to-FPC have many advantages. Strong drop impact resistance, improved drop impact and twisting resistance by corrugated contact structure; strong solder float prevention, improved solder float prevention by nickel plating barrier; strong corrosive gas resistance, improved corrosion resistance to gases, etc. by sealing hole treatment; strong resistance to foreign matter and flux, improved contact reliability by V-groove structure. It can be well adapted in various environments.

1, strong drop impact resistance, through the corrugated type contact structure, through the corrugated type contact structure, for the unavoidable vibration and impact in mobile equipment, must have a fairly high contact reliability. Improved drop shock and twist resistance, the contact part has a high-precision bending and molding function with full spring characteristics. A high level of impact resistance can be realized. High-precision molding is achieved through our core technology, "Precision Metal Processing". This improves the drop impact resistance and torsional insertion/removal resistance of mobile devices.

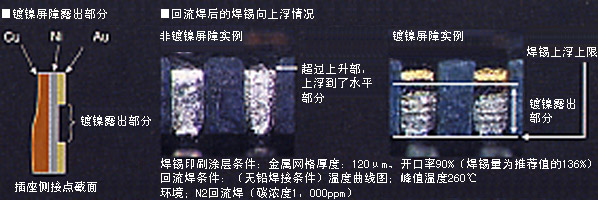

2. Strong solder floatation prevention, nickel-plated barrier structure that prevents solder from creeping, and flux that improves N2 reflow and lead-free soldering to improve the solderability of soldering. In addition, the miniaturization of connectors may lead to solder floatation. In order to improve the performance of preventing the floating of solder, nickel is exposed in the center of the socket contact. This prevents the floating of solder even if the thickness of the contact is thin. It is possible to form a stable soldering arc even if solder is left on the terminal part, and to control the influence of solder on the contact part and the contact spring part.

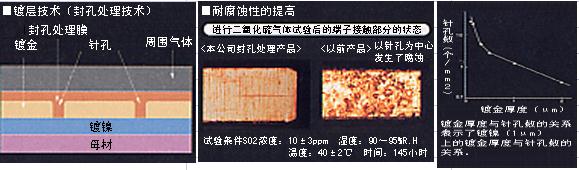

3. Strong resistance to corrosive gases by sealing the holes and sealing the holes. Since the mobile equipment is used in a variety of situations, the surrounding gases (such as exhaust fumes from automobiles) and perspiration, etc., that comes out while carrying the equipment may have an effect on the contact portion. This is a sealing technology that seals pinholes in the plated surface by improving the corrosion resistance to gases and so on. Even with thin gold plating, the same contact reliability as with thick gold plating can be realized. Improved contact reliability for digital signals, improved corrosion resistance, and improved durability for insertion and removal.

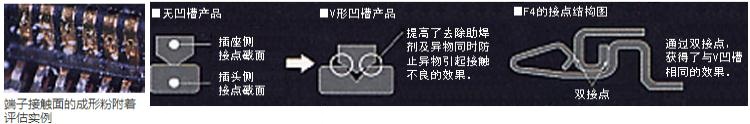

4, foreign matter and flux resistance, through the V-shaped groove structure, 2V-shaped groove structure even for very small structural components, further requires a performance that can work in a variety of environments, storage. Improved contact reliability; the contact part utilizes an edge contact method while increasing the contact pressure per unit area. This improves the effectiveness of removing flux and foreign matter. It also prevents foreign matter from causing poor contact and has the effect of preventing it from happening in the first place; the effect of moving the contact point before and after the V-shaped groove passes through; surface contact → edge contact; 2-point contact; improved contact reliability (prevents foreign matter from causing poor contact).

About EverestElectronics.com Brief description of the company and products sold:

Evergrande Electronic Products is a professional, accurate and vertical electronic industry sales platform focusing on the supply and demand of connectors, wiring harnesses and cables! Specializing in the production / sale of {connectors | wire harness | cable products }; if you want to buy or understand what we can provide connectors | wire harness | cable product solutions, welcome to contact us through the following way.