Categorization:Product Information

1. Strip the outer sheath, armor and inner lining layer. Straighten the cable, clean it, strip the outer sheath of A+ terminal depth (C) long, tie the line, leave the steel armor 30mm, inner lining layer 10mm, the rest of the stripping; copper shielding end with PVC tape wrapped tightly. 2. Fix the steel armor ground line. The steel armor on the paint rust play light, the card has "steel armor ground line" sign ring ground line with large constant force spring fixed in steel armor (in order to be firm, the ground line to leave 10mm-20mm head, constant force spring will be wrapped around the circle, the head of the back fold back, and then use constant force winding). 3.Wrap filler glue. Since the sheath break below 50mm to the whole constant force spring, steel armor and inner protection layer, with filling rubber winding two layers. 4. fixed copper shielded wire. Stuff one end of the other ground wire into the middle of the three-wire core, and then stuff the cushion cone into it, and then use this ground wire to wrap around the root of the three-wire core, and then use the constant force spring to fix it around the outside of the ground wire. 5. Wrap the self-adhesive tape. Wrap a layer of black self-adhesive tape outside the filler rubber and constant force spring. 6. Fix the cold-shrinkage finger sleeve. First of all, the three small support tube at the end of the finger slightly tugged out a little (from the inside and the root of the finger and aligned), and then the finger sleeve into, as far as possible downward pressure, counterclockwise first of all, the large end of the plastic strips out, and then out of the finger end of the plastic strips. Wrap the PVC tape around the finger within 200mm of the finger tip of the finger casing. 7. Fix the cold shrinkage tube. Put the cooling tube to the root of the finger casing, and pull out the plastic strip counterclockwise (do not clutch the unshrinkable cooling tube when pulling out). 8. Strip the copper shielding and outer semiconductor layer. Retain 10mm copper shielding, the rest of the stripped, retain 15mm semiconductor, the rest of the stripped. According to the depth of the terminal to remove the insulation of each phase. Chamfer the outer semiconducting layer and insulator ends with a cutter, and wind the phase color strips according to the original phase color. 9. Wind the semiconducting tape. Wind the semi-conductive tape on the copper shield (and cold shrink tubing wrapped flat). Sand the surface of the insulation layer with sandpaper and clean it with cleaning paper. When cleaning, from the core end, jerk to the outer half-conductive layer, do not come to rub. Apply silicone grease to the surface of the wire core (more coated).10. Fix the cold-shrinking terminal. Slowly pull the support strip inside the terminal until it is aligned with the terminal port. Thread the terminal into the cable core length and install the limit line to the chapter. Gently pull the support strip to shrink the cold-shrink terminal (if the terminal and the limit line are found to be misaligned at the beginning of the shrinkage, it can be corrected by hand), insert the terminal and crimp it. 11. Fix the sealing tube. With filler glue to the terminal crimping parts of the gap and indentation wrapped flat, from the top of an umbrella skirt to the entire filler glue outside a layer of sealant wrapped around the terminal outside the sealant to be wrapped around a layer of PVC tape, otherwise the support strips and their adhesion; sealing tube set in this part of the contraction, such as sealing tube and the gap between the terminals, you can turn over the sealing tube, wrapped around some sealant on the terminal and then sealing the sealing flip rolled back; and then flip up the big end of the finger sleeve , wrap the outer sheath tightly with sealant and clamp the ground wire in the middle of the adhesive strip to prevent water ingress, then flip back to the finger sleeve, and fix the ground wire outside the finger sleeve with tie wire.

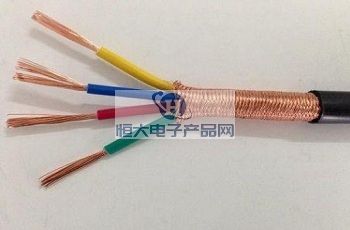

-12, about Evergrande electronic products network platform related to the introduction and sales of products briefly: Evergrande electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand what connectors | harness | wire and cable product solutions that we can provide, please contact the following Division I business personnel! If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ← ¡" to discuss with a person!

-12, about Evergrande electronic products network platform related to the introduction and sales of products briefly: Evergrande electronic products network - a professional agent / production / sales of a variety of {connectors | wiring harness | wire and cable products }; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand what connectors | harness | wire and cable product solutions that we can provide, please contact the following Division I business personnel! If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ← ¡" to discuss with a person!