Categorization:Product Information

Electronic wiring harness is one of the most used connection accessories in electronic devices. In terms of automobile wiring harness, as one of the important components of the car, equivalent to the car's transmission nerve, the car as a whole has the role of signal transmission and control, it can be said that the automobile wiring harness will have a direct impact on the quality and performance of a car. Therefore, the automotive wiring harness in the design, in addition to meet the basic performance requirements of the car, the quality of the wiring harness products itself is also extremely high. The production and manufacture of wire harness products involves a wide range, more requirements, the process is cumbersome, so how to produce high-quality, high-efficiency electronic wire harness products is worth studying the problem. The application of electronic equipment technology in the field of automotive is after years of research, the development has been successfully developed automatic driving, electronic maps, power more optimized system, etc., these technologies are declaring the emergence of intelligent cars. Now intelligent cars, new energy and other cars have entered the ordinary family, the popularity of the strength and depth of the promotion and development, so as an important part of the automobile automotive electronic wiring harness and automotive connector products should be developed along with it, closely follow the development trend of automotive electronics technology.

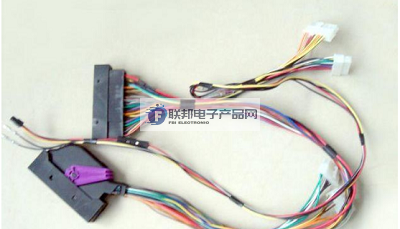

Automotive wiring harnesses have which kinds of process 1, open wire process. The accuracy of the open wire process is directly related to the entire production schedule, once the error is particularly short open wire size, will lead to rework of all stations, time-consuming and labor-intensive impact on production efficiency. So in the preparation of the open wire process must be based on the requirements of the drawings to reasonably determine the size of the wire open wire, stripping size. 2, crimping process. According to the drawing requirements of the terminal type to determine the crimping parameters, the production of crimping operation manual, for special requirements need to be specified in the process documentation and training of operators. For example: some wires need to pass through the sheath before crimping, it needs to be pre-installed wire and then return from the pre-installation station and then crimp; there are also piercing crimp with a special crimping tool, this crimp has a good electrical contact performance. 3, pre-assembly process. First of all, we must prepare a pre-assembly process operating instructions, in order to improve the total assembly efficiency, complex wiring harnesses should be set up to pre-assembly station, pre-assembly process is reasonable or not directly affects the total assembly efficiency also reflects the technical level of a craftsman high and low. If the pre-assembly part of the assembly of the less or assembly of the wire path is unreasonable will increase the workload of the total assembly personnel, slowing down the speed of the assembly line, so craftsmen should often stay in the field and constantly summarize. 4, the total assembly process. Able to compile according to the product development department designed assembly board, design equipment, material box specifications and size and will be assembled all the sheaths and accessories of the number affixed to the material box in order to improve the assembly efficiency. Preparation of each station assembly content and requirements, balancing the entire assembly station to prevent a point of excessive workload, pulling down the speed of the entire assembly line. To achieve workstation balance, process personnel must be familiar with each operation and on-site measurement of working hours, adjust the assembly process at any time.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!