Categorization:Product Information

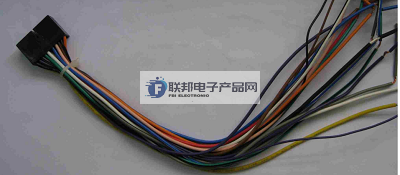

Automotive wiring harness processing functions as the basic vehicle for communication within the automobile. Automotive wiring harness processing is the main body of the automotive circuit network, connecting the electrical and electronic components of the automobile to make it work. Without wiring harness processing, there is no automotive circuitry. Automotive wiring harness processing is made of copper components, contact terminals crimped with wire and cable, and then external pressure insulator or metal shell, the components and wiring harness processing bundled together to form a connection circuit. At present, whether it is gaoji luxury car or economic ordinary car, the form of wiring harness processing is basically the same, composed of wires, plug-ins, packaging tape. Both to ensure the transmission of electrical signals, but also to ensure the reliability of the connection circuit, to the electronic and electrical components to provide the specified current value, to prevent electromagnetic interference with the surrounding circuit, to eliminate electrical short circuits.

A common and prevalent problem in wire harness machining with the following solutions:1. When the rubber housing wears out, the pins for the terminals are removed. It is important that it needs to be pulled back for each hole inserted.

2. This wire is tinned. Once the wire is dipped in tin, it may cause the PVC to shrink by heat. In this case, choose heat-resistant PVC and control the time of tin dipping.3. Insufficient tension after crimping; if the harness processing tension is not reached, you can choose to find the cause from the following aspects:① Whether the crimping range of the terminals and wires is appropriate. ② Design of blade material and structure. ③ Terminal materials, etc. 4. Labeling does not stick. If the labeling does not stick, then do not directly touch the sticky surface with your hands, stick it on a clean metal first, and then stick it on the line one by one.5. How to do the reliability test of cable line? Generally need to test the swing, lifting load and conduction performance. General swing test conditions:swing frequency, lifting load, required zui small number of swings, etc.. Lifting test conditions should include three parameters: lifting load, lifting time, displacement size after lifting.6. How to test the coating of terminals? Salt spray test of terminals can be carried out.7. How to test the tension of dual voltage terminals? Dual voltage terminals should be tested for single conductor tension using the same method as for single conductors.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!