Categorization:Product Information

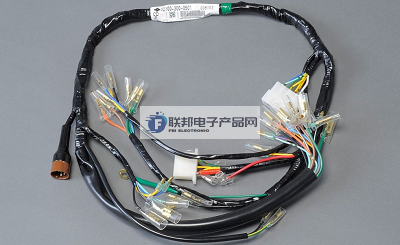

Electronic wire harnesses are an important part of electrical. There is a strict and proper step when using wire harness processing, this step will determine the good or bad of wire harness processing. So every step of the harness production and processing are bixu highly valued and meticulous. Here I will introduce the details of the process of electronic wire harness processing.1. Bundle and protect the front cabin wiring harness cabin working environment is also relatively poor, especially rain and snow, road conditions are bad, by the environmental impact is relatively large. Most of the branches are also wrapped with corrosion-resistant, wear-resistant and other mechanical strength of the bellows, such as PP, PA bellows; some of the branches due to the layout of the body wrapped in PVC pipe, such as the ABS wheel speed sensors, and other branches, and even some of the trunk branches with wear-resistant and high-temperature performance of the cloth-based tape wrapped. 2. Engine harness outsourcing to protect the engine harness is fixed in the engine around the temperature is high, high vibration, high. The working environment is harsh. Therefore, with high flame retardancy, corrosion resistance and mechanical strength of the bellows, such as PA, PPmod bellows, the periphery of the PVC tape wrapped to play a completely sealed role, or the use of high-performance polyester cloth-based tape. Considering the bending direction of the space, some branches can also be wrapped with high temperature PVC pipe.

3.Wrap the door wiring harness around the outside door wiring harness is mounted inside the door. The space is small but protected by an interior panel. It can be wrapped with tape or flowers, and some of the branches can be wrapped with industrial plastic sheeting or PVC pipe. The transition area from the door sheet metal hole to the interior harness also needs to be protected with a tough ji good rubber.4. Wrap the instrument harness outside The instrument harness is fixed underneath the dashboard and has a small working space. Because there are more instrument harnesses and control functions here, the instrument harness has more branches and the whole harness is more compact. However, the environment here is better, you can wrap it with PVC tape or flowers, some branches need to be wrapped with PVC pipe, such as the gas pedal, anquan airbag branch and so on. Generally connected to the audio function of the harness branch with sponge tape package, shock absorption effect is good, to ensure that the signal transmission is good; in order to achieve good noise reduction effect, some parts need to facecloth tape.5. Wrapping the floor wiring harness and ceiling wiring harness roof and floor wiring harness branch most of the time will be mounted with zip ties or carabiners in body sheet metal holes, and there is a good working environment for the protection of upholstery. The trunk of the harness can be wrapped directly with tape or wrapped with flowers, and the entire harness should be soft and easy to install. Depending on the specific branching direction and fixing method, the branches can be wrapped with tape or flowers or protected with PVC pipes. If a part rubs against the body due to shaking, it can also be protected with PVC pipe. A branch of the floor harness is wrapped with facecloth tape.6, heavy truck harness bandage Some heavy truck harnesses working in harsh environments, due to its irregular shape by the space and fixed, the outer perimeter of this type of harness is generally braided mesh, and the inner joints of the harness need to be double-layered heat-shrinkable tubing for heat-shrinking.7, twig paper tape wrapping In order to load the convenience of the wiring harness, some of the branches should be used ahead of time with a beautifully patterned paper tape tie Good; some important parts need to be wrapped with foam pads to prevent damage from collision during transportation, and the periphery should be tightened with fine-grained paper. Fine grain paper tape is easy to tear, quick and convenient for loaders and unloaders to tear the tape, widely used for temporary bundling of wiring harness branches.8. Wrap the positive and negative ji wire harnesses of the battery In general, the battery harness is shorter and connected with the battery. The periphery is usually wrapped with bellows and wrapped with PVC tape. Battery positive and negative ji battery clamps are generally protected by dust caps. 9. winding anquan airbag harness anquan airbag harness is a key part of the automotive wiring harness, its production and processing is particularly important. The outer protection of the harness generally requires yellow bellows and yellow PVC pipe, wrapped in yellow tape, play a good warning.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!