Categorization:Product Information

In today's world is the world of high technology, a variety of electronic devices have long been into our lives, this commodity to facilitate our daily life, change the old habits of the past, produced a lot of convenience. However, we have to understand that most of the electronic equipment will appear on the electronic harness, if not, but also with some items to replace. Its role is indispensable. The other has not been too much too much explanation, the following by the Huicheng yuan harness brand for the guys to explain the basic information of the electronic device harness processing steps in detail. Electronic device wiring harness processing step by step detailed description, then electronic device wiring harness is what? Electronic harness with the most common words is to use electronic devices to manipulate the key and output of the transmission line.

Electronic device harness processing steps: 1, cut the line to see whether the cable specification type is appropriate; limit is in line with the requirements. 2, peeling the skin to see whether the peeling mouth is flush, can not be stripped core wire, teaming wire, etc., peeling limit is appropriate. 3, teaming to deal with the limits of shearing and trimming is appropriate, whether shearing and trimming is flush, shearing and trimming teaming can not be hurt when the core wire. 4, peeling the skin to see whether the skinning mouth is flush; peeling limit is appropriate; there is no stripping the core wire, broken copper wire; half-stripping conductor and insulator can not fall. 5, set to reduce the tube to see the reduction of tube limit, type is appropriate. Limit is appropriate; there is no peeling injury to the core wire, broken copper wire; half peeling when the conductor and insulator can not fall. 5, set to reduce the tube to see the reduction of tube limit, type is appropriate. 6, in advance of the preparation of the solder wire to see the temperature of the furnace is appropriate; in advance of the preparation of the solder wire before the core wire will be combed well, whether there is a bifurcation of the copper wire, bumpy, discounts and other phenomena; in advance of the preparation of the solder wire after the bifurcation of the copper wire, the majority of the copper wire, Copper wire jagged and scalded insulation skin and other phenomena. 7, solder wire to see whether the temperature of the electro-chromium iron is appropriate; can not be scalded insulation skin, tin point should be moistened, Wuxi City, pointed, not good fake welding, empty welding. 8, terminal pressure recognized terminals, cable specifications are appropriate; terminal pressure there is no flare period, tilt, insulation skin and core wire is too long or too short. 9, terminal piercing to see whether the RF Connector, terminal type is appropriate; terminal there is no damage, deformation and other phenomena; terminal there is no leakage of insertion, wrong insertion, puncture is not timely and other phenomena. 10, line socket view of the RF connector type is appropriate; line orientation is appropriate; core wire is not damaged, exposed copper, burned; socket in time or not. 11, blowing to reduce the reduction of tube reduction tube is not, not scalding the insulation skin. 12, the assembling machine Shell shell whether to install the reverse, there is no scratch, burr and other poor, there is no leakage of components, screws there is no screwing hair, air oxidation, color loss, loose and other poor, assembled in accordance with the poor; such as the shell is oriented, then it must be assembled in accordance with the requirements. 13, affixed to the label to check the contents of the logo is appropriate, clear, no word breaks the appearance of the logo; logo limit is appropriate; logo is not smudged, damaged; logo is affixed to the direction is appropriate. 14, affixed to the direction is appropriate. 14, affixed to the logo is appropriate. 14, playing the bundle line with view of the bundle line with the specification, color, direction is appropriate; no crack, loose phenomenon. 15, injection molding process to see whether there is a stain on the abrasive tool, molding position whether there is undercooked, bubbles, adhesion is poor, hard bottoming is poor and so on. 16, power plug molding to see whether there is no damage to the power plug molding, uneven, undercooked, burrs, dirt, flow lines and other poor, recognized metal materials. Poor, recognized metal material terminals invisible change, damage, copper exposure and other poor. 17, electrical equipment viewed in accordance with the relative product view of the specific guidance ticket requirements to carry out the view. 18, the appearance of the view should pay attention to if it is able to see all the new items must be viewed. According to the above you can probably grasp the electronic device harness processing steps. Electronic wiring harness in today's society can be seen from time to time, such as common electrical products and computers are with it, and electronic wiring harness in this electronic equipment also has a very key effect.

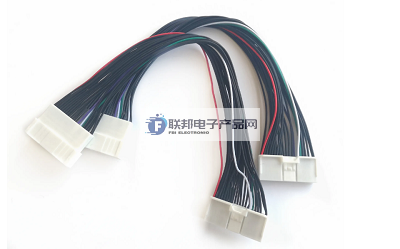

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!