Categorization:Product Information

Wire harness processing automatic leveling needs jingque reference surface (line). Generally to control the height as a priority, it is appropriate to walk the wire; when the thickness control is the main method, the floating reference beam method. The general bottom layer uses walking wire, and the middle and surface layers use the floating reference beam method. The reference wire rope method is to install the reference wire rope on both sides of the pavement, but pay attention to:The spacing of the supporting reinforcement of the wire rope should not be too large, generally 5-10m; the reinforcement should be 1-2mm above the design elevation, and the reinforcement should be ensured to have accurate elevation in the paving process. The processing of wire harness should work continuously at a uniform speed without stopping, and it is forbidden to be fast or slow. In the leveling process, should try to avoid stopping work, the daily stoppage time should be placed at one end of the structure is scheduled to do shrinkage seam position. In the unlikely event of a stoppage in the middle of the process, the harness processing punch should be locked to avoid sinking; when the temperature of the mixture is higher than 100 degrees, the pause time should not exceed 10 minutes. When the pause time is 30 minutes or the temperature of the mixture is below 100 degrees, the joints shall be rejoined in the same manner as cold joints are handled.

Wire Harness Processing is a machine used to adjust the quality of cement concrete floor, usually used to adjust the strength, flatness and levelness of the floor. It can adjust the cement concrete floor in places with a large area, such as industrial plants, large shopping malls, warehouses, and offices of large corporations. Several self-control elements are used in the harness processing to monitor the elevation of the whole leveling head in real time, and the monitoring frequency is relatively high. It can be used about ten times per second. The leveling and leveling of the ground adjusted by wire harness processing is great, almost three times the level of the adjusted ground, and the density and strength increase. It is also very convenient to pour all kinds of concrete on the ground with wire harness processing, which can help to save a lot of labor, and also can greatly shorten the construction time, which is a good choice for leveling the ground. Using harness processing technology:Wolf Warrior-concrete harness processing is to use the scraper to scrape away the raised concrete and initially scrape it flat to meet the design requirements. Adopting double-wheel automatic walking system, the vibration frequency is 4000 times/minute, which drives the whole vibrating plate to vibrate the concrete together. Wolf Warrior harness processing concrete construction width is 2.5m... Laser concrete bench beam processing is a kind of laser as a reference plane, real-time control of the flat head, to achieve high flatness of concrete. It is a means to reduce the construction cost of enterprises. In the economic recession, flooring enterprises will choose the construction mode of wire harness processing to save fixed investment, reduce labor costs and lower operating costs. In fact, these are not the weiyi reasons for enterprises to choose concrete wire harness processing. Wolf Warrior Concrete Laser Booth Harness Processing uses laser technology to level the concrete floor, which is a leveling machine with high flatness and small error. The vibration frequency of the machine is 4000 times/minute, which ensures the denseness of the concrete floor and one-time molding. Simple and flexible operation, high degree of automation, construction efficiency is greatly accelerated, especially suitable for large area floor construction. As long as 6-8 workers can realize the workload of 3000 square meters per day and 400 square meters per hour, which greatly reduces the labor cost and labor intensity.

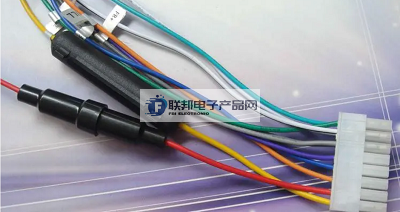

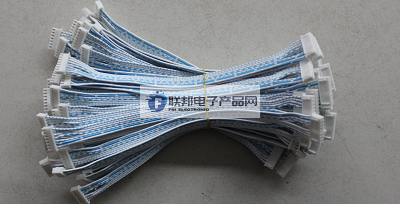

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable production]; if you have a relevant [connectors | wiring harness | wire and cable production] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; if you have a relevant [connectors | wiring harness | wire and cable production] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" and discuss with a person! If you have related [connectors | harness | wire and cable production] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" to discuss with a person!