Categorization:Product Information

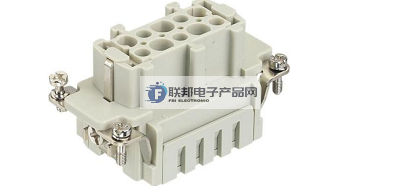

As we all know, heavy duty connectors are connectors that are used to cope with the harshest industrial environments. Because they can withstand harsh environments, they are widely loved and widely used in industries such as construction machinery, robotics, rail transportation, and power automation. Today's article will take you to understand the relevant knowledge of heavy duty connectors.

First of all, the use of heavy-duty connectors in the environment 1. high-temperature environment First of all, in a high-temperature environment, basically all the equipment and components are a requirement that needs to be strictly controlled. How to maintain efficient operation in a high-temperature environment? So what is the use of heavy-duty connectors in high-temperature environments like? The metal material and insulation of a heavy duty connector determines the temperature of the connector's operating environment. High temperatures can damage the edge material, resulting in lower insulation resistance and voltage withstand. For metals, high temperatures can cause the contact vice to lose elasticity, accelerate oxidation, and deteriorate the coating.2. Humid environmentSecondly, in humid environments, the electrical equipment of heavy-duty connectors may cause electrical breakdown accidents. The humid environment causes the absorption and diffusion of water vapor on the insulator surface, which easily reduces the insulation resistance. Long-term high humidity environment will cause physical deformation, decomposition and escape of products, respiration effect, electrolysis, corrosion and cracks, which are the greater hazards to heavy-duty connectors. Therefore, in the high temperature and high humidity environment, how to strictly control the heavy duty connector is our guarantee to improve the quality. When the heavy-duty connector is mated with the connector, it needs to be designed to be firmly mated in order to make a tighter connection, which means that the mating strength is relatively high. As a result, the interaction between insertion force and withdrawal force will tend to cause wear and tear of the heavy-duty connector. Well, if heavy-duty connectors want to reduce wear, you can look at the following good methods:The strength of the gold plating layer on the contact surface can be increased, which can effectively reduce friction. The contact surface can be nickel plated before gold plating, so the friction will be less than the friction of direct gold plating on copper. The main difference between normal connectors and heavy duty connectors is the number of connections and load capacity. Heavy duty connectors are able to withstand a larger number of connections than normal connectors and can withstand larger connection loads. This makes heavy duty connectors more suitable for industrial applications such as robotics, automation equipment and production lines. In addition, heavy-duty connectors are typically more vibration and environmental resistant, withstanding higher vibration and shock loads, as well as higher temperatures, humidity and corrosion. Compared with ordinary connectors, the price of heavy-duty connectors is usually slightly higher, but considering its higher reliability and service life, heavy-duty connectors may be a better choice in industrial applications. Second, how to reduce the wear and tear of heavy-duty connectors? At the same time, the thicker the nickel layer, the better the abrasion resistance of the gold plating layer, the smoother the surface, the lower the friction, the less wear and tear, standardized operation can reduce the wear of the plug-in.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!