Categorization:Product Information

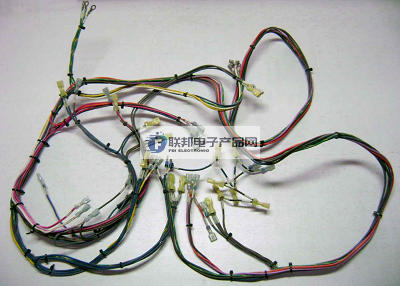

Industrial wiring harnesses are identical components in a variety of electronic devices that provide a variety of important services to certain load source groups. As an intermediary of these services, strength is undoubtedly an important element to harness. Industrial wiring harnesses are required to have satisfactory strength. If it is not strong enough, it simply breaks down due to some external factors such as high winds, icing or improperly timed repair. And if you choose a conductor with a thin cross-section, it is simple that it will overheat when using an overload current and maintain a damaged insulation, which can cause a serious fire in the circuit. Another point is that the conductor chosen must not have excessive voltage loss.

When choosing an industrial wiring harness, you need to choose it based on your circuit. If you are choosing a low voltage harness, choose it based on its heat generation and then test its voltage loss and strength. If it is a high-voltage harness, then you need to select the wire based on its current condition and then measure its heat generation and voltage loss. What problems may occur during the use of industrial wire harnesses?1. Oxidation of conductor joints: In the ecological environment of humid and corrosive air, an oxidized layer is easily formed on the conductor, and copper oxide will appear on the copper wire. The conductivity of aluminum oxide is more likely to form on aluminum wires. In the workshop, the conductor is corroded by acidic air for a long time, and the conductor forms an oxidized layer on its appearance, resulting in higher contact resistance. When the power is turned on, high temperatures are generated. In serious cases, even the red wire will be lost in real time, and then there is no accident.2. Industrial wiring harnesses are contaminated by dust: in open areas such as construction sites and threshing plants, dirt and dust usually penetrate into the splices of the conductors, interfering with the contact between the rails, leading to overheating of the splices, and burning of combustible materials around the threshing plant. A number of electrical fires result. Measures to avoid industrial wiring harness accidents: 1. Minimize wire adapters. Generally use the whole wire, there should be no seams, characterized by the roof. 2. wire connection should be in accordance with the standard, as far as possible to increase the contact surface of the wire joints, to avoid the use of hook connectors and terminals connected to the first tightening of multi-stranded steel wire, do not show hair. It is necessary to bend the wire into a circle and place it on the binding post, tighten the washer screws on the washer and tighten the cover. It is easy to use soldering or crimping to connect large cross-section wires and aluminum core wires.3. When crimping method can be used, it can be coated with conductive paste. Copper and aluminum transition joints are easy to use; copper and aluminum can also be connected. A thin layer of copper or tin is applied to the nose of the copper wire, which is then connected with aluminum wire.4. The direction of the electronic connectors is staggered. The connectors of each phase wire should be intertwined. The exterior of the adapter should be wrapped in black rubber tape with a large cross-sectional area. The interior should be coated with yellow wax cloth or yellow wax cloth to improve insulation. It should not be present in the electrical structure. It is important to take precautions and pay attention to all the above processes to avoid fire accidents due to poor electrical connections and touching.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!