Categorization:Product Information

Industrial connectors as industrial power and signal transmission connection equipment, can be used according to the environment and the object has a lot of contact information, the user in the purchase of their own actual situation should be based on their own choice of connection method. Here by Huicheng yuan electronic for everyone to introduce the industrial connector connection.

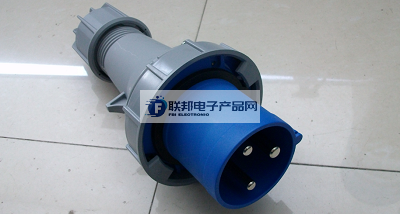

1, piercing connection industrial connector piercing connection is also known as insulation displacement connection, with the use of convenient connection, high reliability and low cost features, the current industrial connector in the printing industry is widely used in the connection mode of the connector. The connector in the connection does not need to poke the cable insulation, only with the help of the connector on the "U" contact reed sharp into the insulation can be, so that the cable conductor into the industrial connector groove fixed to achieve the cable and the connector of the close connection. 2, solder connection of the industrial connector solder connection is the use of the solder material and is soldered between the formation of the connection. Solder material and be welded between the formation of a continuous metal layer, according to this characteristic can be derived from the use of this type of connection to have weldability. At present, the common industrial connectors in the welding of silver, tin alloy and gold and other metals. Solder connection can be divided into reed type and pinhole type two kinds, including pinhole type welding end with drilled holes and arc notch; reed type welding end with notched tabs, punched eye tabs and ordinary tabs three kinds. 3, cabinet connection industrial connector on the cabinet connection is mainly near the frame of the user needs to be blindly connected to the equipment of a connection, this cabinet connection allows electrical equipment units independent of each other, lightweight, and Maintenance does not reduce the reliability of electrical equipment and other advantages. However, it should be noted that the industrial connector cabinet connection when the operator can not know the connection, so we need a positioning device to assist in connecting to ensure that the connection is reliable, at present, domestic manufacturers generally take the spring-loaded, floating contact design to ensure that the correctness of the cabinet connection. 4, plug and play connection of the industrial connector plug and play connection is one of the more common connection, it is the connector plug and socket in a horizontal position, the connector plug and socket, the connector plug and socket, the connector plug and socket in a horizontal position. Connector plugs and sockets in the horizontal direction can be realized by moving the plug, the entire connection process does not require selection and optional equipment, can be realized quickly and easily connected and separated from the action. At present, the pull-in connection can be divided into two structures: pin pull-in and ball pull-in. Because this connection eliminates the mechanical locking mechanism, so once mistakenly inserted is very difficult to pull out. 5, snap connection is currently the most common industrial connector snap connection connection connection, in the connection between the most common application of electrical components, snap connection snap are marked on the correct direction of snap locking, and the user can be viewed through the side of the industrial connector nut connector snap in real time whether all completed. 6, threaded connection 6, threaded connection threaded connection as an industrial connector connection mode "big brother", but now in use is very rare, only in some larger size or the existence of strong vibration environment will use threaded industrial connectors. Threaded connectors have the advantage of high reliability, it is through the strong friction of the nut gear to fix the cable (plus the house loose fuse after the effect is better). The disadvantage of threaded connections is that they are slower to dismantle and time-consuming to tighten and unthread.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | wire harness | wire and cable products] sales / resources and promotion needs, please click on the "¡¡ Business Cooperation ←" to discuss with a person!