Categorization:Product Information

Regardless of what industry, the quality of the product is their top priority, if even the quality of the product is not pass, the other is empty talk. So how much do you know about the quality requirements of electronic connectors, about the quality requirements of electronic connectors knowledge, in the following Huicheng yuan connector company will explain for you. Even though every we need to deal with quality, but let us go to the accurate definition of what is quality is also very difficult. ISO9000 on the quality of the following definition: a set of intrinsic characteristics to meet the degree of requirements. We have a different understanding of this definition, here with the connector industry to talk about what is quality or what is quality.

Let's start with a simple example. A connector factory is holding a meeting on the topic of "Quality Improvement". Business executives and product development director's opinion is that the performance of the product to improve quality, will inevitably increase costs. But the quality and production supervisor's opinion is that the improvement of performance, product qualification rate increases, the cost is bound to decrease. At this point, the views could not be harmonized. In the end, the meeting ended because of the lack of unity of opinion. In fact, the root of the problem lies in the different understanding of the concept of quality. In the connector industry, quality (quality) has at least three layers of meaning: First, the connector design quality (quality), that is, the connector design can achieve the degree of design goals. But the establishment of the design goals is not an easy process, there is also a design goal of the quality of the problem, the accurate design goals (or good quality design goals) need to be strongly supported by the customer, try to participate in the supply side and the customer repeatedly communicate with the two sides to reach a complete understanding of the two sides to clearly understand the expression of the design goals, the understanding of the design goals are completely consistent, otherwise, even if the other work related to the customer to do a perfect job, the customer may not be very satisfied, this is a good idea, the customer may not be very satisfied. Otherwise, even if other work related to the customer is done perfectly, the customer may not be very satisfied, which is the step of the quality management process, but also a prerequisite. We may have such an experience: the customer has no complaints about the product, but is not satisfied, the reason is that although the product meets the requirements of the design goals, and the design goals are recognized by the customer, but the design goals and can not be a good realization of the product's functionality, so the customer did not complain, but the product's functionality is not satisfied. Let's say the customer requires the development of a connector, one of the design goals is RF leakage is not greater than -60dB, the design of the connector test results also show that the requirements of the design goals, but the customer found that even if less than -60dB leakage of the connector is still a significant impact on the surrounding a component. Although the customer did not complain, he was not satisfied with the connector. Now assume that the design goals have been fully agreed upon, one of the requirements of the design goals is that the connector's insertion and removal life is not less than 10,000 times, the pull-out force is not less than 200 grams. According to customer requirements, connector design engineers with C5240 material design a required shrapnel, according to the analysis of the shrapnel in the working state when the stress reaches 900MPa, reasonable design requirements with SH hardness of C5240, the engineers due to inexperience, the choice of H hardness of C5240, the results of the samples in the life of 8,000 times, the pull-out force is less than 200 grams, the connector Shrapnel can not meet the requirements of the design goals. This situation is the connector design failed to meet the design goals, is the connector design quality issues. Another example, the customer's requirements for a particular connector is: life of 5 years, contact resistance 10mOhm (greater). The supplier's corresponding design is, forward force 80 grams, silver plating 2 microns. Customers do incoming inspection, the product can achieve the contact resistance of 20mOhm (greater) requirements, 3 years later, the customer perceived that the connector has a poor contact phenomenon, test the contact resistance found in some of the connector contact resistance is greater than 200mOhm! Supplier after the fact to find the connector plating design standards found that the forward force should be greater than 200 grams to ensure that the contact resistance is less than 10mOhm, and internal test data also confirmed the design program is 80 grams of forward force, silver plating 2 microns. And internal test data also confirmed the theory. The design solution could not meet the requirements of the corresponding design objectives. This is also an example of a connector design that fails to meet the design objectives. Second, the quality of the connector design specifications (quality), that is, the connector design parameters (specifications) to achieve the degree of design intent, or the expression of the design to achieve the degree of design intent. Assuming that a connector designer intends to design a 6pin connector, pitch 8, pitch tolerance in 0.15 within the drawings are labeled as follows: this labeling allows the two ends of the pin (pin and the last pin) between the tolerance accumulated: 0.15 X 5 = 0.75, contrary to the design intent, it is likely to result in the connector can not be mated. In fact, we have no shortage of poor quality connector design specifications, there are a number of drawings of the design information is incomplete. Such as we often come across not marked plating measurement points, plating hardness, plating color of the connector terminal diagram. Therefore, one of the principles of design is that the design of drawings, specifications, standards of interpretation is. If there is ambiguity will inevitably make your design intent compromise, or even the opposite. This is why there are a variety of drawing standards. Even if there are a variety of drafting standards, there are differences between the standards, and even very different, such as China, Europe, the former Soviet Union with the Angle projection method and the United States, Japan, Taiwan, China, using the third Angle projection method. Angle of the upper and lower left and right views is the third angle of the lower right and left views, the expression of the product structure is very different. Third, the production quality of the connector (quality), or connector manufacturing level, that is, the connector can achieve the degree of design specifications. This is the meaning of the quality of our more common connector. Such as a connector shell drawing labeled length is 10 +/-0.1, the length of production is 10.12, the size of the unqualified; such as the connector terminal drawing requirements plating gold 0.76um thick, and plating the measured plating thickness of the terminals for the 0.86um, the plating to meet the specifications; and then purchased back to the beryllium copper strip material C172000 TM06 tensile strength of less than 1000MPa, is bad, because the relevant standards require the specifications of beryllium copper belt tensile strength higher than 1070Mpa (see ASTM B 194) It can be seen from the connector product life, from the customer to generate new connector demand, to the connector design, production, sales, after-sales service, to the connector is gradually eliminated, after a lot of cycles and links, how much is involved inside the Connector quality (quality) of the connotation of different levels. Even from the above analysis of the three levels can also reflect the quality of the connector (quality) of the characteristics: connector quality (quality) at each level of meaning is not the same. Meet the design specifications of the connector does not necessarily meet the design intent, to meet the design intent of the connector does not necessarily meet the design objectives. Meet the design goals do not necessarily meet the functional requirements of the application, we deal with customer complaints or discuss the connector quality (quality) to be clear about the meaning of the specific level refers to, in order to achieve the target, otherwise there will be different views, arguments, can not form a unified action and measures, as mentioned in the example at the beginning of this article some supervisors believe that improving the quality of the increase in costs while some supervisors believe that improving quality As mentioned in the example at the beginning of this article, some supervisors believe that improving quality will increase costs while others believe that improving quality will reduce costs. In fact, this involves different meanings of quality, improve the design quality of the connector (quality), enhance product performance, often increase costs and improve the production quality of the connector (quality), reduce waste naturally reduce costs. Product quality (quality) to stand in the customer's point of view, the company's height to understand, to recognize, to practice. After reading the above, you should have a basic understanding of the quality requirements for electronic connectors. Huicheng yuan connector company, in all the connector production and manufacturing processes, are adhering to the principle of quality, pay close attention to product quality, never relax. All of our connector products have passed the ISO quality certification system, in line with international environmental requirements, the majority of customers can rest assured that procurement!

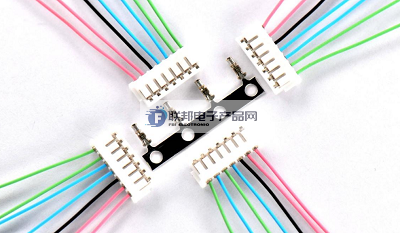

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!