Categorization:Product Information

As a member of the connector industry, have you ever been troubled by how to choose a connector, the following Huicheng yuan connector company engineering will teach you some tips for choosing a connector. Connector selection should consider both performance requirements and economic factors, performance must meet the requirements of the system electrical equipment, the economy must meet the requirements of value engineering. In principle, the selection of connectors should consider the following four aspects: connector interface (SMA, SMB, BNC) electrical performance; cable and cable mounting; connection form (PC boards, cables, panels, etc.); mechanical structure and plating (military, commercial)

1, the connector interface electrical performance connector interface is usually determined by its application, but at the same time to meet the requirements of electrical and mechanical properties.BMA type connector is used for frequencies up to 18GHz low-power microwave system blind plug connection.BNC type connector using bayonet connection, mostly used for frequencies lower than 4GHz RF connection, widely used in the field of network systems, instruments and computer interconnections. TNC in addition to the screw port, its interface and BNC similar to 11GHz can still be used in vibration conditions, excellent performance.SMA screw connector is widely used in aviation, radar, microwave communications, digital communications and other military and civilian fields. Its impedance has 50Ω, with a flexible cable when the use of less than 12.4GHz, with a semi-rigid cable with a higher use of frequency up to 2635GHz; 75Ω in the digital communications on the application of promising. SMB volume is smaller than the SMA, for the insertion of the self-locking structure, to facilitate rapid connection, the most classic application of the digital communications, is the replacement of the L9, the business of 50Ω to meet the 4GHz, 75Ω for the 2GHz. SMC and SMB are similar, because of the screw port to ensure stronger mechanical properties and a wider frequency range, mainly used in military or high vibration environment. n-type screw port connector with air as the insulating material, low cost, impedance of 50Ω and 75Ω, the frequency up to 11GHz, usually used in regional networks, media distribution and test equipment. rf radio frequency connector electrical performance mainly contains the following aspects: impedance: the connector should be located in a wide area, the media distribution and test equipment. Aspects: impedance: the connector should be matched to the system and cable impedance, it should be noted that not all connector interfaces are in line with the 50 Ω or 75 Ω impedance, impedance mismatch will lead to a decline in system performance. Voltage: Ensure that the use can not exceed the connector's higher voltage value. Higher Operating Frequency: Each connector has a higher operating frequency limit, and some commercial or 75Ω designs have lower operating frequency limits. In addition to electrical performance, each interface form has its own unique features, such as: BNC for bayonet connection, easy to install and inexpensive, in the low performance electrical connection is widely used; SMA, TNC series for the nut connection, to meet the high vibration environment on the requirements of the connector, SMB has a fast connection disconnect function, and therefore more and more favored by the user. 2, cables and cables mounted on cables: cables are often used only for the purpose of connectors, due to their low shielding performance. Shielding performance is low, usually used only to consider the impedance of the system, a typical application is the TV antenna. TV flexible cable for the TV cable variant, it has a relatively more continuous impedance and good shielding effect, can be bent, low price, widely used in the computer industry, but can not be used for the requirements of a higher shielding performance of the system. Flexible cable eliminates inductance and capacitance and is mainly used in instruments and buildings. Flexible coaxial cables are the most prevalent hermetically sealed transmission cables because of their special properties. Coaxial means that the signal and ground conductors are on the same axis, and the outer conductor is also known as braided coaxial cable due to the delicate braid composition. This cable is also adapted for use at high frequencies and high temperatures. Flexible coaxial cable with a tubular shell instead of braided layer, effectively making up for the shortcomings of braided cable at high frequencies when the shielding effect is poor, the frequency is very high usually use semi-rigid cable. Cable mounting: connector installation method there are two main: welding center conductor, spinning shield; crimp center conductor, crimp shield. Other methods are derived from the above two methods, such as: welding the center conductor, crimp shield. Method one for the absence of special installation tools for the occasion; due to crimping mounting method of high efficiency, reliable termination performance, and the design of special crimping tools to ensure that the mounting out of each cable assembly is the same, so with the development of low-cost mounting tools welding center conductor crimp shield will be increasingly popular. 3. Connection form connectors can be used for RF coaxial cables, printed circuit boards and other Connection interface. Practice has shown that a certain form of connector and a certain type of cable to match, generally small outer diameter cable and SMA, SMB and SMC and other small coaxial connectors connected. You can refer to the cable size list to select the appropriate connector. 4. Mechanical construction and plating of the connector structure will greatly affect its price. Each connector design includes both military and commercial standards, with military standards manufactured to MIL-C-39012. All copper parts, PTFE insulation, and gold plating inside and out provide the most reliable performance. Commercial standard designs use inexpensive materials such as cast brass, polypropylene insulation, and silver plating. Connector housings use materials such as brass, beryllium bronze, tin bronze, aluminum, and stainless steel. The center conductor is typically gold plated due to its low resistance, corrosion resistance and excellent containment. Military standards require gold plating on SMA, SMB, and silver plating on N, TNC and BNC, but because silver is easy to oxidize, many users prefer nickel plating. Connector insulators are PTFE, polypropylene and toughened polystyrene, of which PTFE has better insulating properties but is more expensive to produce. Connector materials and structures affect the connector processing difficulty and processing efficiency, so users should be based on their own application environment reasonable choice of good performance-price ratio of the connector.

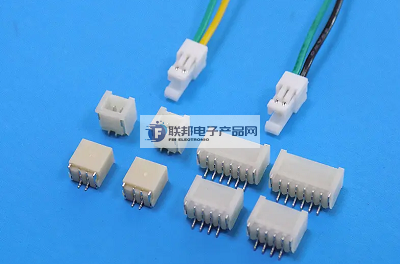

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!