Categorization:Product Information

The diversity of electronic connectors on the market, can not be separated from the efforts of major manufacturers of research and development, then you know what the electronic connector R & D requirements? On the knowledge of electronic connector R & D requirements, Huicheng yuan electronic connector company will invite professional electronic engineers to explain the specific requirements of the connector R & D. The electronic products demand is growing like crazy, and then people's demand for electronic connectors has also skyrocketed. Crazy growth in demand for electronic products, and then the demand for electronic connectors is also rising, in the face of increasingly high demand, the major manufacturers have also begun to face higher challenges and technical requirements.

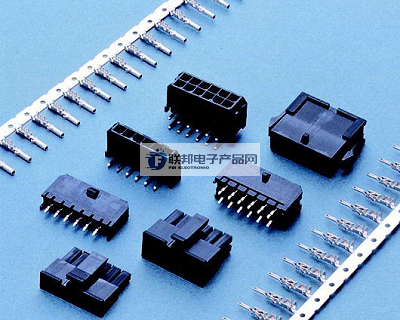

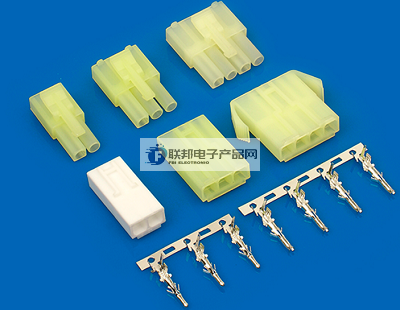

To gain a foothold in the connector industry, connector R & D companies must step up the pace of industrial restructuring, increase scientific and technological innovation and capital investment, in order to produce high-performance connectors to meet market demand, in line with the times. According to professional connector R & D engineers, the requirements of the connector manufacturing industry is mainly focused on: First, a good processing base process a good connector needs to be designed, equipment, technology, the perfect combination of three aspects. At the same time this is a high demand for equipment supporting the higher technical barriers. Second, the need for a high level of mold design due to different shapes of terminals, connectors have no structure, how to carry out a reasonable design is very important, if the structure is not reasonable will lead to unqualified products. Third, high-precision equipment connector terminals require high precision processing equipment, foreign equipment accuracy can reach ± 0.002mm, while the general domestic equipment can only reach ± 0.01mm. in the connector interface miniaturization, high data transfer rate and other trends, the future connector mold requirements will become more and more demanding, which is the connector mold equipment, materials, quality and so on, the mold using the Punching speed has reached 500 rpm-3000 rpm, which is undoubtedly a technical challenge for connector R & D enterprises.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!