Categorization:Product Information

1. Front cabin wiring harness outer wrapping protection cabin wiring harness working environment is also relatively poor, especially the rain and snow and bad roads, by the environmental impact of the big, most of the trunk is also corrosion-resistant, wear-resistant and other mechanical strength of the bellows wrapping, such as PP, PA bellows; a part of the branch due to the layout of the body of the car to take into account the curvature of the wires using PVC pipe wrapping, such as the ABS wheel speed sensors, and other branches, and even a part of the trunk using a better abrasion resistance and high temperature cloth-based tape wrapping. Even a part of the trunk is wrapped with cloth-based tape with good abrasion resistance and high temperature resistance. From the front cabin through the sheet metal holes to the driver's cab wiring harness excessive area needs to be protected with rubber parts to avoid sheet metal holes scratches or abrasion of the wiring harness, but also play a good waterproofing effect, to prohibit the rain along the wiring harness into the driver's cab. 2. engine wiring harness outside the bandage to protect the engine wiring harness around the engine is fixed to a high temperature, high vibration, the working environment, so the use of high flame retardant, corrosion-resistant, high mechanical strength corrugated pipe wrapping. Therefore, the use of high flame retardant, corrosion-resistant, high mechanical strength corrugated pipe wrapping, such as PA, PPmod corrugated pipe, and the periphery of the whole wrapped with PVC tape to play a complete sealing effect, or the use of high-performance polyester cloth-based tape, part of the branch to take into account the bending of the space towards the high temperature resistant PVC pipe can also be used.

3. Door Harness Outer Wrap The door harness is mounted in the 4-door, and although the space is small, it is protected by the interior panel, and can be wrapped with tape, either all the way around or in a pattern, and some of the stubs can be wrapped with industrial plastic sheeting or PVC tubing. The transition area from the 4-door sheet metal hole to the interior of the harness also needs to be protected with a very tough rubber part. A left front door wiring harness rubber parts shown in Figure 7. 4. Instrumentation wiring harness outside the wrapping instrument harness is fixed under the instrument panel, the working space is small, because of the instrument wiring harness and control functions here more, so the instrument wiring harness branch more, the wiring harness is more compact as a whole, but the environment here is relatively good, can be wrapped with PVC tape or flower wrapping, a part of the branch needs to be wrapped with PVC pipe, such as the accelerator pedal, the airbag branch, etc.; the connection to the audio function of the wiring harness branch is generally sponged with a sponge, the wiring harness branch is usually wrapped with a sponge. Some branches need to be wrapped with PVC pipe, such as accelerator pedal, airbag branch, etc.; the branches of wiring harness connecting to audio function are usually wrapped with sponge tape, which has a good shock absorption effect and ensures good signal transmission; some parts need to be wrapped with velvet tape in order to achieve a good noise reduction effect. 5) Floor and ceiling harnesses: Most of the trunks of the roof and floor harnesses will be mounted with zip-ties or snaps in the holes of the car body sheet metal and protected by the interior trims, which has a better working environment, and the trunks of the harnesses can be wrapped with PVC tape or flower wrap. The overall wiring harness should be soft and easy to install. Branches according to the specific branch direction and fixing method can be fully wrapped with tape or wrapped with flowers, can also use PVC pipe protection; if a part of the body due to friction caused by shaking and friction, can also be taken to protect the PVC pipe. 6. Heavy duty wiring harness wrapping some heavy duty wiring harnesses working in harsh environments, due to its irregular shape by the influence of the space and fixing, the periphery of such wiring harnesses are usually used to braid the mesh, and the wiring harness internal contacts need to be protected with a double layer of wire harness protection. The protection of the contacts need to use double-layer heat-shrinkable tubing heat-shrinkable.

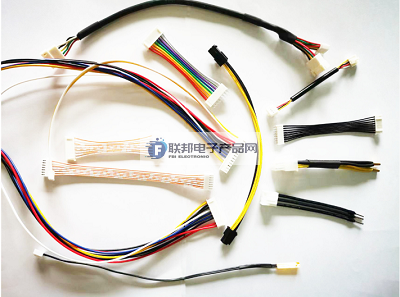

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!