Categorization:Product Information

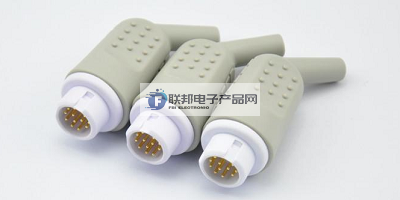

The design of medical devices is highly dependent on efficient underlying electronic interconnect systems. Therefore, connector design and the selection of the right connectors is critical. When designing medical devices, engineers are faced with many trials and tribulations and extremely complex choices that do not occur in other industries. Medical devices need to be durable and reliable, and the conditions of use are often very harsh, which affects factors such as liquids, sterilization, physical and electromagnetic interference, as well as a very high number of plugging and unplugging. These medical devices are highly dependent on the effectiveness of the underlying electronic interconnect system. Connector design is an integral part of the design process, and choosing the right connector is critical. One of the first considerations for engineers is to decide whether to use an off-the-shelf connector, a hybrid version or a customized solution. Off-the-shelf products are already on the market and are available in a variety of configurations. These products tend to require lower engineering and tooling investments, but have longer lead times and higher unit costs. Hybrid versions (hybrid) on the existing connector to provide customized overmolded (overmolded) features. These products offer improved performance and aesthetic value over off-the-shelf products, and lower design and engineering costs than fully customized connectors, but with longer lead times. A custom solution is a product designed and manufactured for a specific customer, device or application. Using customized connectors will make it easier to integrate components or electronic assemblies, as well as add marking or logos. The initial investment in engineering and tooling is generally higher, however, depending on the volume, this type of solution can be more cost effective in the long run.

In many cases, customized or hybrid solutions are preferred over off-the-shelf solutions, especially where there are special considerations. For example, in a disposal room where dozens or more different cables and connectors are in use, medical personnel run the risk of misconnecting cables and equipment. Off-the-shelf connectors can be equipped with different colored overmolded housings, a hybrid product that clearly identifies which connector goes to which piece of equipment. In the case of cardiac arrest, the equipment used on the patient usually needs to be able to withstand a defibrillation pulse of 5,000 to 8,000 volts. In such cases, insulation, spacing, materials and air gaps can all be customized to meet the specific needs of the application. Other examples of customized solutions include designing the connector to prevent incompatibility upon insertion. Or, given ergonomics, the ideal size of a medical interconnect system needs to be large enough to be easily maneuvered by the intended user and be very intuitive to insert. For hybrid or custom medical connectors, the design, tooling and manufacturing process typically takes four to eight months. Early in the design process, the team clearly defines the requirements, which involve electrical (voltage, cardiac shock, bandwidth/data rate, etc.), mechanical (cable diameter, ergonomic characteristics, expected flex life, expected insertion and extraction forces, etc.), and environmental (sealing and ingress protection, cleaning, sterilization, etc.) considerations. After the specifications have been determined and the design operations (including the physical model) have been agreed upon, prototyping can begin. When selecting hybrid or customized medical connectors, it is important to have teamwork between all the units involved. In this way, it is possible to produce a medical device that performs well enough in the field and meets all mechanical and electrical requirements, including connectors and cable assemblies.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!