Categorization:Product Information

Portable and wearable medical devices represent a huge market with high growth rates in the medical technology industry. Patient monitors are evolving from stationary devices at the hospital bedside to small, lightweight, integrated devices that provide patients with sufficient mobility to remain at home and in the community while under the care of a physician. Advanced technologies are driving innovation in mHealth services, and exciting telemedicine and eHealth devices for diagnostics and monitoring are enabling physicians to communicate with more and more people in a more efficient manner, even when patients are located in remote locations around the world. Better patient comfort and mobility depend on the ability to pack more functionality into thinner and smaller devices. Evolving and highly reliable devices that can seamlessly perform in non-traditional healthcare environments transcend the limitations of the clinical environment and present significant challenges for medical device designers. Compliance to Ensure High Reliability and SafetyMedical technology represents a highly regulated industry with extremely stringent medical grade guidelines for high-density medical devices used in home medical telemetry and portable applications. The regulations pertain to material sourcing, manufacturing and packaging processes. Multiple industry regulatory ratings and environmental ratings exist for electronic components, including U.S. Food and Drug Administration (FDA) certification, ISO 13485, ISO 10993, RoHS, and REACH, and suppliers may also be required to comply with ISO 9001 quality management systems and ISO 14001 environmental management systems, as well as FDA and other industry specifications, including AAMI-53 and IAMI-53. FDA and other industry codes, including AAMI-53 and IEC60601 global safety standards, UL/CSA, etc., play a critical role in the design standards for medical technology. the FDA's categorization and general control standards are based on the intended use of the device and take into account the potential risk to the patient. Class II and III devices require more stringent definitions in terms of performance and risk management than lower-risk Class I devices. Registered and certified manufacturers are required to meet a variety of stringent quality system requirements, including a myriad of inspection, tracking and traceability standards. FDA registration of a supplier further ensures the quality and safety of electronic components used in disposable, portable, and wearable medical devices. Pointing the Way to Interconnects Connectors are ubiquitous in devices used in all areas of healthcare - medical imaging, therapeutic, minimally invasive surgical instruments, implantable electronics, patient monitors, and sensors of all kinds. Selecting the interconnect technology for a particular application is a critical step. In past designs, multifunctional devices could require a myriad of connectors. Today, connector options often combine copper power and signal lines, fiber optics, fluid or gas connections, and even RF antenna interfaces, all packaged into a single integrated interface. The right choice of connector can reduce total cost of ownership for manufacturers, enable more compact packaging, and improve the delivery of healthcare services. Therefore, it is important to successfully point the way through the maze of connector technology. Before identifying connector types, designers first need to identify each connection type, i.e., whether it is board-to-board, wire-to-board, wire-to-wire, panel-mount or in-line termination, in addition to whether it is a receptacle through-hole termination or surface-mount termination. The relevant standard should specify the number and type of interface contacts and the configuration of the associated cables. Whether a particular cable is for ECG, defibrillator, power, analog, digital, bandwidth, fiber optics, or a combination of these will determine the diameter, length, shape, and material of the cable. In each design, there are package size constraints, in addition to manufacturer preferences for the desired physical dimensions of the final product, as well as branding requirements, such as logo markings and serialization processes for product tracking, among others. Connector specifications are largely dependent on the intended use in a real-world environment. The functionality of the application, as well as any potential for misuse, together determine the physical properties required of the connector. In a portable device, the design requirements would be much higher, thus allowing the patient to move freely. The design specifications met by portable medical devices are much closer to those of a smartphone than those of a traditional medical device used in a clinical setting. The number of times a medical technology device is connected may range from a single-use sensor in a disposable sensor up to tens of thousands of plugs and unplugs in an MRI coil or a portable blood glucose meter worn by a mobile medical patient twenty-four hours a day, seven days a week. The construction of the device worn or carried by the patient must be able to function under a wide range of conditions. In field environments, such as a patient's home, there are all kinds of temperature and humidity levels, and shock, vibration, and accidental drops occur far more often than in clinical environments where devices are operated by specialized personnel.

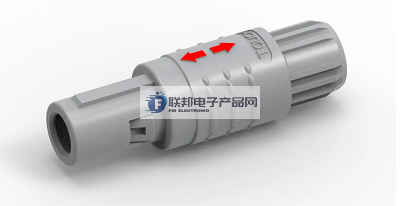

Mechanical Properties of Connectors A variety of highly durable materials are suitable for the manufacture of lightweight portable and wearable medical technology devices. Connector contact seats and plating are typically made of metal, while shells and strain reliefs are made of medical grade plastic or metal. Gold-plated contacts generally offer better performance in harsh environments. While tin materials are more economical, gold plating provides the most reliable contact and achieves the highest number of plugs and unplugs. In addition, nickel-palladium-gold plating has been proven effective and widely adopted in the industry. Devices with connector interfaces that can be pulled out properly and are well designed can be visually inspected to minimize debris buildup. If contaminants are found to be present, they can be removed before they impact performance. The process of sterilizing medical devices, specifically contact with sterile wipes, gamma radiation, vinyl gas exposure, autoclaving, and the Sterrad process, also has an impact on material selection and design. Each sterilization method creates different contact levels, exposure to a variety of chemicals, reactions, and risks to the integrity of the connector. Medical technology applications often require connectors that are resistant to fluid intrusion, in most cases requiring IP6 or IP7 levels of protection. Depending on how they are connected to the device, medical connectors are categorized as locking or non-locking. In assemblies that connect a patient to a portable device, it is often necessary to achieve a solid locking connection to avoid accidental disconnection. Additionally, a connector may need to be securely disconnected where axial forces are applied to avoid accidental injury to the patient, connector or cable assembly. Even in non-locking connectors, medical cables need to provide a rigid connection between the plug and socket. A loose connection can lead to intermittent contact, creating unwanted noise or signal degradation that can interfere with the performance of the device. The choice of pins and slots, as well as the physical design of the plug and socket, allows for control of insertion and retention forces. Retention force is defined as the firmness with which a connector is held by the socket. If a connector is desired to have a high number of insertions and withdrawals, retention force is generally achieved by metal pins and slots. In some cases, for example, if a handheld defibrillator requires a securely latching connector, it may be reasonable to enclose a flexible cover over the connector to protect the latching mechanism. If the retention force is achieved through the pin slots and the connector housing does not have sufficient friction, the retention force may be increased by a design so that the axial force applied to the cable is not applied directly to the shaft in the connector from which the external force is to be removed. Conversely, non-locking connectors can be designed so that the axial force applied to the cable can disconnect the connector through the axial force applied to the cable. The use of right-angle connectors provides another way to increase retention and prevent accidental unplugging. Measuring retention force at pre-established intervals during insertion and removal ensures that the required retention force is maintained over the design life of the connector. Verification testing of medical connectors plays a critical role in ensuring that specification requirements are met or exceeded in the final design. Three tiers of connector design solutions Finished connector solutions can provide medical technology manufacturers with a way to utilize a variety of economic technologies that have been tried and true in other industries. For example, high-performance medical circular connectors are a cost-effective option, featuring a well-recognized contact design, highly durable insertion force, and a body style made of plastic or metal materials that can withstand the effects of sterilization processes. Circular connectors with lightweight, medical-grade plastic housings provide high-quality electrical performance at a competitive price for a wide range of applications including medical catheters and other portable devices. In some applications, standard off-the-shelf connectors are not sufficient. Custom or hybrid connectors may be more appropriate for the design requirements. Designing a completely new connector allows for greater design flexibility and offers the most comprehensive range of options, but at a much higher cost. Manufacturing custom connectors generally requires injection molded rigid plastic insulators into which the pins and/or slots are inserted. Components are clad with rigid materials to ensure robustness of construction and to achieve physical strength. Secondary overmolded materials provide the connector with the color, finish, and appearance desired by the OEM. Customized connectors often require higher engineering and fabrication costs up front, which can be well worth the investment. Design elements can be better addressed with fewer compromises. Unique pin socket patterns or connector shapes can prevent the insertion of incompatible connectors, thereby ensuring patient safety. Or, it may be necessary for the connector shape to closely match the device form factor, optimizing portability. Where a single connector cable assembly must carry multiple types of voltages and signals, the need for customized connectors may be even greater, as a standard connector will not meet the standard requirements for that situation. Hybrid connector solutions can achieve a balance between price and functionality. Hybrid products use tried-and-true technologies that take advantage of the basic components of standard connectors and optimize the functionality without incurring the additional costs required to manufacture a new type of connector. Hybrid connectors may incorporate the use of structurally robust overmolded housings to improve grip, as well as the use of pre-molded chassis or molded rings to allow for stress relief or increased IP protection. Hybrid connectors cost less, while the look, feel, and functionality of the finished product offers most of the performance benefits required for customized connectors. Additionally, designing hybrid connectors reduces development time. Leveraging the industry's better connector technologies Medical technology manufacturers need to adopt the industry's better variety of technologies to provide medical product lines with high-quality compatible products to meet the complex medical needs of the MID (Molded Interconnect Device)/LDS (Laser Direct Structuring) can provide three-dimensional selective tracking capabilities, and has a very high degree of flexibility in the use of injection molding plastics to achieve its soldering, plastic welding, MID-LDS 3D custom assembly solutions simplify the manufacturing of miniature connectors, antennas, and sensors by placing special emphasis on functionality, space, weight, and cost. These assemblies combine MID technology with LDS antenna expertise to enable fine-pitch, three-dimensional circuits in a stand-alone, compact molding device for high-density implantable and wearable patient monitors.LDS uses fewer components, which improves performance in applications such as medical catheters, as compared to larger, less optimally-designed processing devices or assemblies. The technology is particularly well suited for wireless remote and sensor-based patient monitoring applications (e.g., a glucose meter that sends readings to a physician's office via a remote base station-connected device). Informed decision making on connectors to streamline the design and manufacturing process is available to experienced medical component suppliers to provide guidance to designers to ensure full compliance in terms of specifications, risk assessment, cost estimation, and test validation for fully compatible electrical, signaling, and mechanical interconnect products for portable and wearable medical devices.

2, on the federal electronic products network platform related to the introduction and sales of products brief: federal electronic products network - a professional agent / production / sales of all kinds of [connectors | wiring harness | wire and cable products]; if you have a related [connectors | wiring harness | wire and cable products] purchasing / sourcing needs or would like to buy / to understand which connectors | wiring harness | wire and cable products we can provide solutions, please contact our business staff below; If you have related [connectors | harness | wire and cable products] sales / resources and promotion needs, please click on the ¡¡ Business Cooperation ← ¡" and specialists to discuss!